From Wind Farm to Car Park: Europe’s First Blade-Built Facility

Interactive exploration of how 57 decommissioned turbine blades found new life in Lund, Sweden

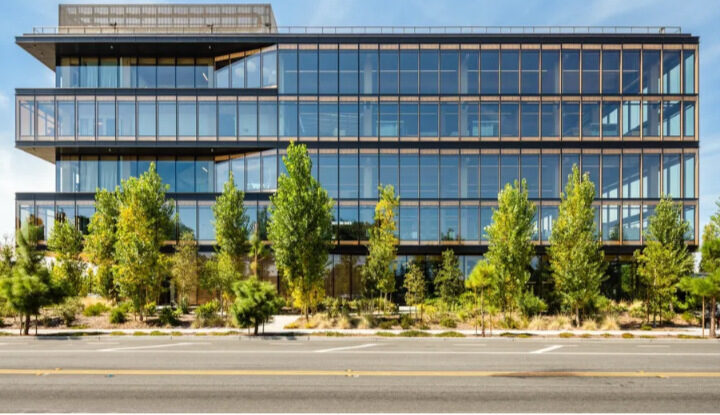

The Niels Bohr car park in Brunnshög, Lund, where decommissioned wind-turbine rotor blades form the building’s curtain-wall façade. Photo: Hadil El-Imam, Vattenfall

A Circular Economy in Action

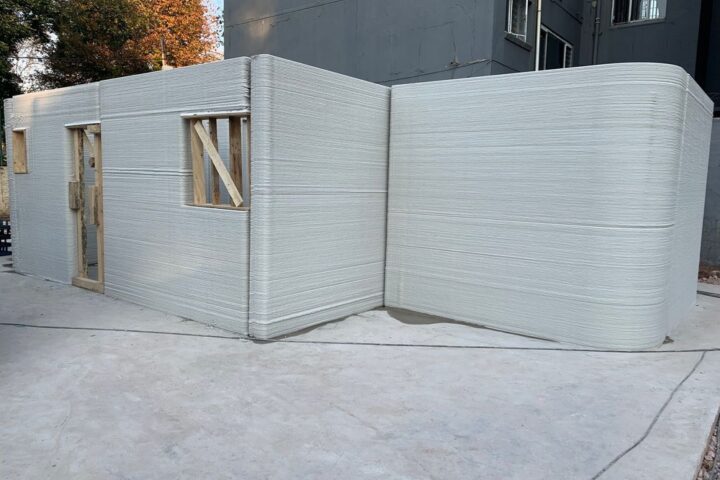

In Lund’s Brunnshög district, Lunds Kommunala Parkeringsbolag opened the Niels Bohr car park using 57 decommissioned wind-turbine rotor blades donated by Vattenfall. The blades serve as curtain-wall façade elements in a facility that combines solar panels, battery storage, and EV charging infrastructure.

The Blade’s Journey: Click Each Stage

Origin: Nørre Økse Sø Wind Farm

The 57 rotor blades originated from Vattenfall’s now-decommissioned Nørre Økse Sø wind farm in Denmark. After generating electricity from North Sea winds for years, these blades reached the end of their operational life in wind energy production.

Vattenfall operates over 1,400 wind turbines across several European countries, making blade circularity a critical operational priority as the first generation of wind farms reaches decommissioning age.

The Recycling Challenge

Wind turbine blades are made from layered composites—glass and carbon fiber reinforced with resin—engineered to survive decades of harsh weather. This exceptional durability creates recycling difficulties.

Architect Jonas Lloyd conceived the Lund project after reading about waste challenges in the American wind industry, where many decommissioned blades are buried due to recycling limitations. “I read that in the US, many of the blades are buried, and I thought they could be put to better use. It’s not just an environmental problem, but also a waste,” Lloyd explained.

Architectural Integration

The architect and his colleagues designed the car park with the blades serving as non-load-bearing curtain wall elements—structural coverings that protect the building’s interior without supporting weight.

Beyond the blade façade, the building integrates rooftop solar panels tied to a storage battery that enables nighttime EV charging. The design pairs blade elements with pollinator-friendly planted boxes, creating an integrated approach to energy generation and biodiversity support.

Vattenfall’s Circular Strategy

Vattenfall has established a corporate commitment to ban landfilling of turbine blades and achieve 100% circular outflow of blades, nacelle covers, and nose cones by 2030.

The company’s blade strategy follows a reuse hierarchy: first investigating whether decommissioned turbines can be sold to another operator or project, then exploring repurposing options for blade materials—including frames for solar panels, insulation material, and even skis—before considering mechanical or chemical recycling processes.

“This is visible and concrete proof that sustainability can meet the cost, schedule and safety requirements of a project,” says Anne Mette Traberg, Vattenfall’s Country Manager for Denmark.

Future Applications

Paul Myllenberg, CEO of Lunds Kommunala Parkeringsbolag, reports that his organization manages 28,000 parking spaces across the municipality. Despite initial skepticism when the blade-façade drawings were first presented, the board’s willingness to proceed proved essential.

“Fortunately, we have a courageous board,” he says. “It turned out really well. Reality exceeded expectations.”

Of the 57 blades Vattenfall donated, several remain without assigned uses. LKP has launched a public competition inviting suggestions for additional applications, with the winning proposal earning a month of free parking in municipal facilities.

Above all, I am pleased that we are promoting sustainability and that the building has become a symbol of sustainability. It should serve as an eye-opener. When you see the building, you should stop and think: they managed this, what can I do?

Circular vs. Linear: Understanding the Difference

Click to explore different approaches to material lifecycle

- Materials designed for extended use and multiple lifecycles

- Components reused, refurbished, or repurposed before recycling considered

- Example: Wind blades become building façades, bio-based materials replace conventional options

- Waste streams converted into resources for new applications

- Focus on maximizing material value across entire lifecycle

- Materials extracted, used once, then discarded

- End-of-life typically means landfill or incineration

- Example: Traditional blade disposal through burial

- Continuous demand for virgin raw materials

- Limited consideration of post-use material fate

- 57 blades from decommissioned Danish wind farm reused as curtain walls

- 365 parking spaces across 5 floors with 40 EV charging points

- Rooftop solar panels connected to battery storage system

- Pollinator-friendly plants integrated into façade design

- Part of Vattenfall’s 100% circularity target by 2030