A school in India is poised to become the first building constructed from Sugarcrete, an innovative low-carbon alternative to traditional bricks and concrete. Sugarcrete is made from sugarcane by-products, specifically bagasse, which is the fibrous residue left over after sugar sap extraction. By combining bagasse with bespoke sand-mineral binders, Sugarcrete bricks are created, offering a carbon footprint that is approximately 20% of that of traditional bricks. This groundbreaking material was developed by the University of East London’s Master of Architecture and Sustainability Research Institute in collaboration with Tate & Lyle Sugars. In recognition of its environmental benefits, Sugarcrete has been nominated for the prestigious Earthshot Prize.

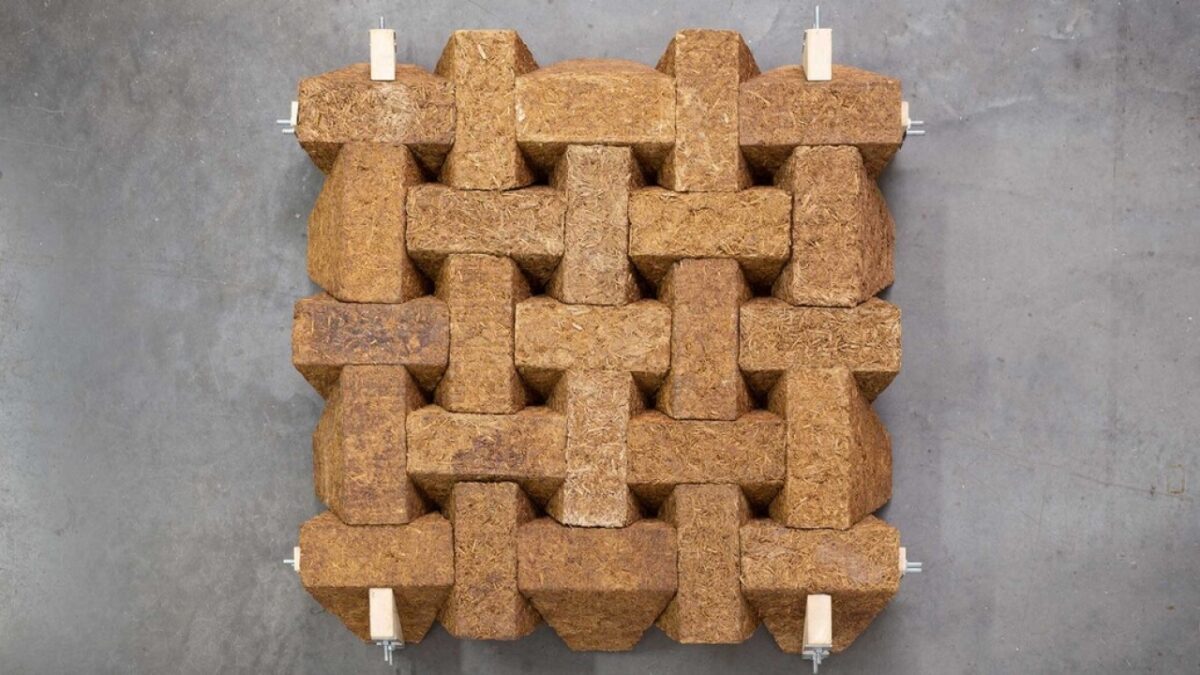

The University of East London, in partnership with Grimshaw Architects, recently unveiled a prototype demountable floor-slab made from interlocking Sugarcrete blocks. This technical application demonstrates the material’s structural capacity and opens up exciting possibilities for its use in construction. UEL is currently in discussions with a company interested in building a school near a sugarcane plantation in India, which would utilize bagasse from production mills to produce Sugarcrete as a cost-effective and sustainable alternative to traditional concrete.

Sugarcrete offers significant advantages over conventional building materials. Its lightweight nature, with blocks that are four to five times lighter than concrete blocks, reduces material weight and facilitates easier handling during construction. Additionally, Sugarcrete has a curing time of just one week compared to the 28 days typically required for concrete production. The embodied carbon of Sugarcrete is eight times lower than the average UK brick and 4.5 times lower than concrete, making it an attractive option for reducing carbon emissions in the construction industry.

Sugarcane production generates a vast amount of bagasse fiber waste, approximately 600 million tons, from an annual production of two billion tons of sugarcane. Sugarcrete harnesses this abundant by-product, providing a sustainable building material that combines structural efficiency with environmental responsibility. With its low carbon footprint, insulation properties, fire resistance, and simplified supply chain, Sugarcrete has the potential to revolutionize the construction industry and contribute to achieving net zero emissions.

The development of Sugarcrete involved a comprehensive digital toolchain for manufacturing, incorporating material computation, parametric design, and robotic manufacturing. The interlocking system used in the project enables the construction of large structures using small, discrete components without the need for mortar. This system, along with the casting process employed, minimizes material waste and allows for formwork reuse, simplified mass production, and Design for Manufacture and Assembly (DfMA) opportunities.

The Sugarcrete project emphasizes ethical considerations, aiming to establish fair and robust supply chains that benefit both producers and users. The team is committed to sharing their insights with producer communities in the Global South, rather than seeking to control the production process through patents. By focusing on carbon reduction, social sustainability, and environmental impact, Sugarcrete addresses the urgent need for sustainable solutions in the construction industry.

Similar Post

Through the adoption of materials like Sugarcrete, the construction industry can significantly reduce its negative environmental impact and contribute to a more sustainable future. This innovative building material demonstrates the potential of utilizing agricultural and industrial by-products, offering a new architectural language that celebrates the unique qualities of natural materials. As the demand for sustainable materials increases and economies of scale are realized, prices are expected to decrease, making natural materials like Sugarcrete even more attractive and accessible.