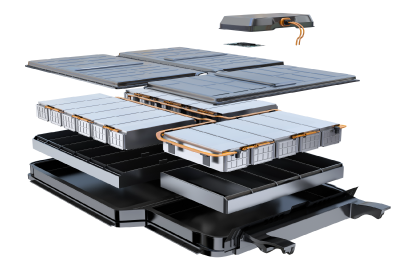

In the dynamic realm of electric vehicles (EVs), the quest for safer and more efficient lithium-ion (Li-ion) batteries is relentless. Stepping into this arena, the Polyplastics Group, renowned for its expertise in engineering thermoplastics, has unveiled its Durafide PPS 6150T73. This material isn’t just another addition to the market; it promises to redefine the benchmarks of heat resistance and thermal insulation for EV batteries.

“The transformative electric vehicle segment demands continuous innovation,” a statement from Polyplastics said. “Our Durafide PPS 6150T73 is a testament to this commitment, showcasing enhanced performance during thermal runaway scenarios.”

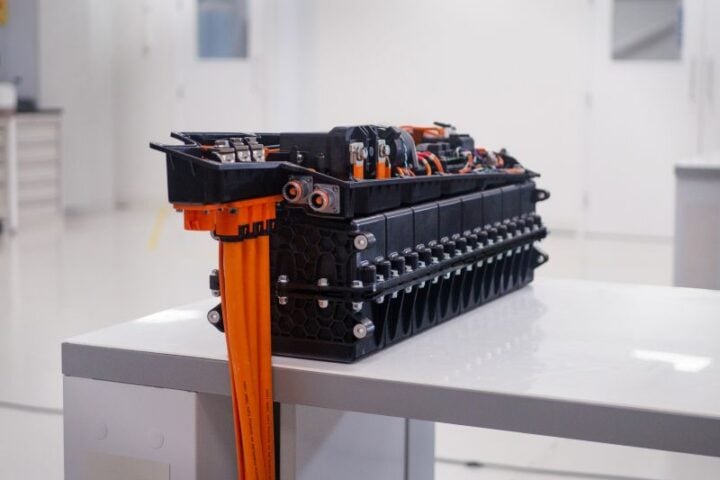

For the uninitiated, thermal runaway in Li-ion batteries (LIBs) is a significant concern. It’s a situation where the battery heats uncontrollably, potentially culminating in fires. During such events, temperatures can soar between 800°C to 1,000°C in a LIB cell, with the expelled gases reaching a staggering 700°C to 800°C. The aftermath? Potential fires, especially when accidents or unforeseen incidents occur.

Traditionally, to combat this, manufacturers employed structural insulative sheets and plates. While they served the purpose, they came with baggage—increased weight and space consumption. “These insulative structures, though functional, aren’t the most efficient. They add to the weight and take up valuable space,” the spokesperson added. This is where Durafide 6150T73 steps in, offering a compact solution without compromising on safety.

But the prowess of Durafide PPS 6150T73 isn’t limited to just heat resistance. It boasts optimal properties for crucial EV components, including busbars and module covers. “The high-purity linear PPS ensures robustness and impact resistance, a critical aspect for EVs,” mentioned a Polyplastics engineer. Furthermore, its near-white hue offers design versatility, allowing manufacturers to tint it based on their preferences.

Similar Posts

However, while the introduction of Durafide PPS 6150T73 is undoubtedly a leap forward, it’s essential to tread with caution. The material’s real-world performance over time remains under scrutiny. As the EV market burgeons, staying ahead of challenges and continuously innovating is the need of the hour.

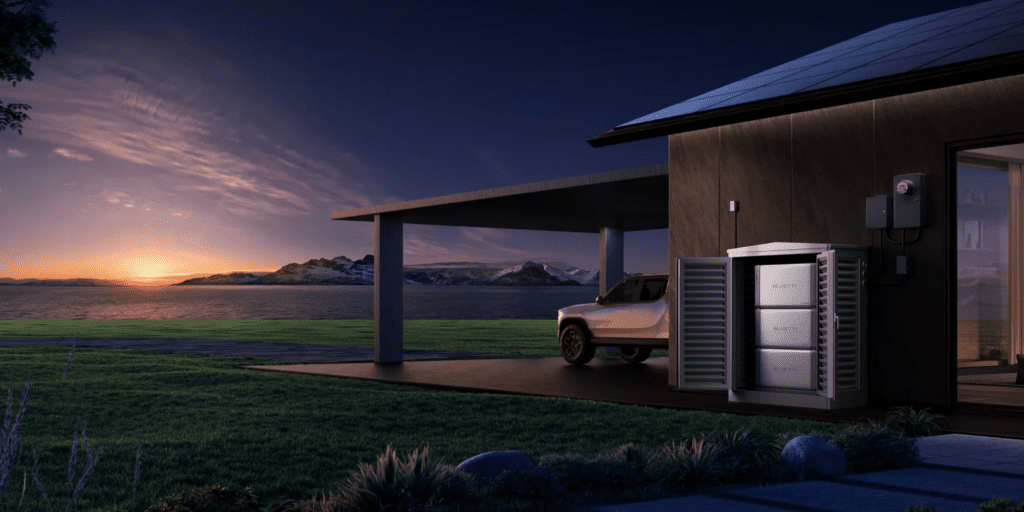

It’s also worth noting the rare but severe risks associated with EV battery fires. They’re not just challenging to douse but have been known to reignite weeks after the initial incident. Such realities underscore the importance of materials like Durafide PPS 6150T73 in the industry.

Polyplastics’ legacy in the domain of engineering thermoplastics is well-established. With a product portfolio that spans POM, PBT, PPS, LCP, PET, COC, and LFT, their global footprint is undeniable. “With over five decades in the industry, our focus remains on creating advanced solutions tailored for a dynamic global marketplace,” shared a senior executive from Polyplastics.

The unveiling of Durafide PPS 6150T73 by the Polyplastics Group is a significant stride in EV battery safety. As the narrative around EVs continues to evolve, materials like these will play a pivotal role in sculpting a safer, more sustainable vehicular future. Yet, as always, a discerning approach, backed by rigorous testing and research, will determine the true impact of such innovations.