MIT engineers have developed a revolutionary new type of solar cell that is ultra-lightweight and flexible and enabling it easy to install on any surface. These fabric type solar cells are much thinner than a human hair and are made of semiconducting inks. These new-age solar cells can be printed using scalable manufacturing processes. They are incredibly durable and can be attached to lightweight fabric which makes them super portable and easy to deploy in emergencies. In addition to being easy to transport and set up, these solar cells are also exceedingly lighter than traditional panels. Weighing just one-hundredth of conventional solar cells, they are able to generate 18 times more power-per-kilogram. They can be worn as a power fabric or quickly and easily installed on fixed surfaces which makes them highly versatile and reliable source of energy.

MIT’s groundbreaking ultra-lightweight solar cells can be easily attached to a wide range of surfaces due to their thin and flexible design. These solar cells can be laminated onto sails, tents, tarps, and even the wings of drones, making them a convenient and renewable energy source. The integration of these cells onto the wings of drones allows for an extended flying range. To point a few possibilities, boats equipped with these solar cells on their sails can harness energy while sailing, and tents or tarps with these cells can be used during disaster or similar operations. This innovative solar technology can be easily integrated into built environments with minimal installation requirements, making it a versatile and practical solution for a variety of applications.

Thin & Light Solar

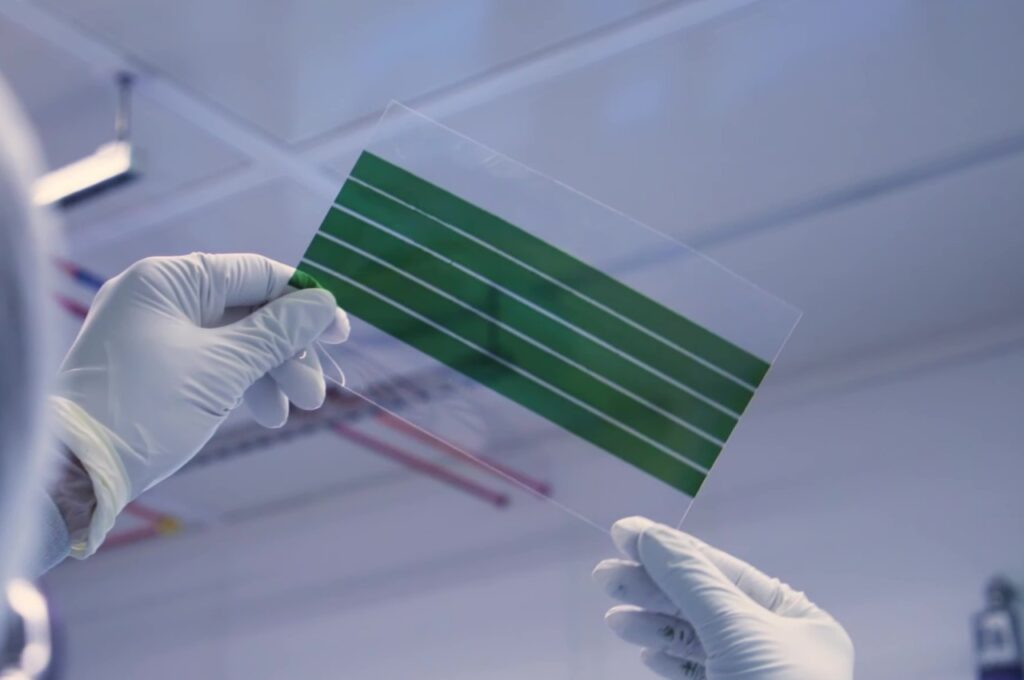

Conventional silicon solar cells are often encased in glass and framed with heavy aluminum, which makes them fragile and difficult to use in a variety of settings. However, a team from ONE Lab developed a new type of solar cell six years ago that is ultra-thin and lightweight, allowing it to be placed on top of a soap bubble. These thin-film solar cells were initially fabricated using vacuum-based processes, which can be expensive and hard to scale up. In contrast, the latest variant of these solar cells from ONE Lab can be produced using simpler and more cost-effective printing processes.

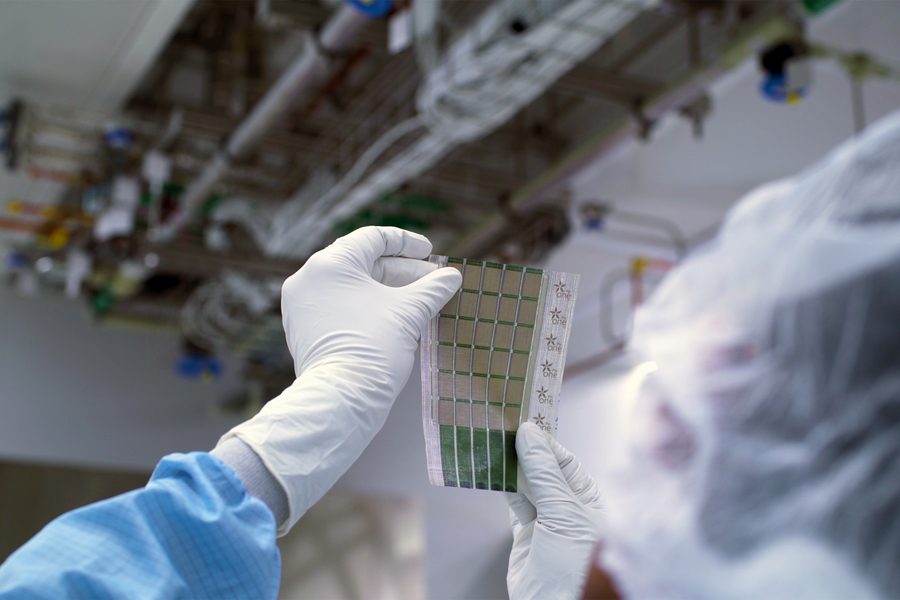

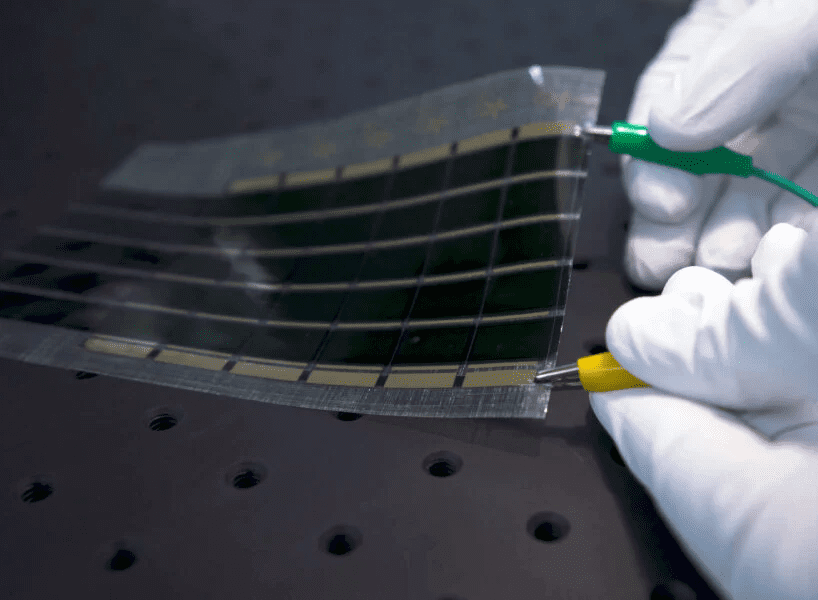

To create these solar cells, they used nanomaterials in the form of electronic inks that were coated over a prepared, releasable substrate using a slot-die coater. An electrode was then added to the structure using screen printing, creating a solar module that was about 15 microns thick. However, these thin, freestanding solar modules are prone to tearing and are difficult to handle, making them challenging to deploy. To overcome this problem, the researchers looked for a substrate that would provide flexibility, strength, and low weight, and they found that fabrics were the ideal solution. These fabrics allowed the solar cells to be mechanically resilient and flexible, while also being lightweight and easy to handle.

“While it might appear simpler to just print the solar cells directly on the fabric, this would limit the selection of possible fabrics or other receiving surfaces to the ones that are chemically and thermally compatible with all the processing steps needed to make the devices. Our approach decouples the solar cell manufacturing from its final integration,” Mayuran Saravanapavanantham, an electrical engineering and computer science graduate student at MIT

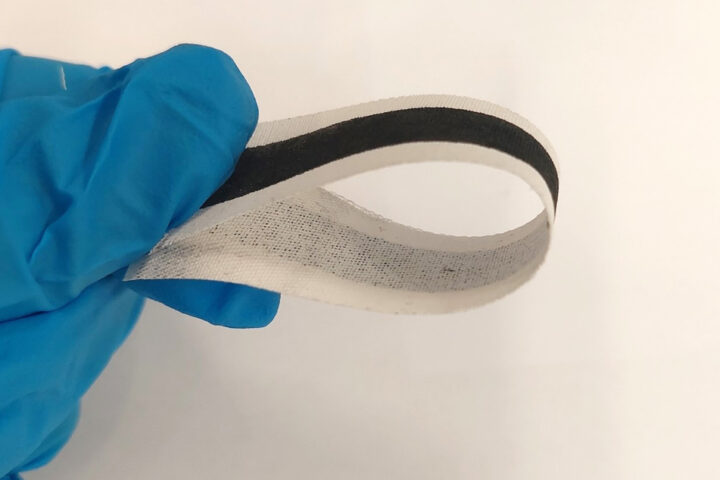

The MIT researchers identified an ideal material for their lightweight, flexible solar cells: a composite fabric called Dyneema that weighs just 13 grams per square meter. This fabric is made of extremely strong fibers that have been used to lift sunken ships from the bottom of the ocean. To create the ultra-light and mechanically robust solar structure, the researchers added a layer of UV-curable glue, which is only a few microns thick, to adhere the solar modules to sheets of Dyneema fabric. The result is a durable and lightweight solar structure that is easy to handle and deploy in a variety of settings.

Better Than Traditional Solar Panels

The MIT team tested their ultra-lightweight solar cells and found that they could generate 730 watts of power per kilogram when freestanding and about 370 watts-per-kilogram when deployed on high-strength Dyneema fabric. This is about 18 times more power-per-kilogram than conventional solar cells. In addition to being extremely efficient, these solar cells are also highly durable, retaining more than 90% of their initial power generation capabilities even after being rolled and unrolled over 500 times.

“A typical rooftop solar installation in Massachusetts is about 8,000 watts. To generate that same amount of power, our fabric photovoltaics would only add about 20 kilograms (44 pounds) to the roof of a house,” says Mayuran.

While these cells are much more flexible and lightweight than traditional cells, they would need to be encased in a protective material to guard against deterioration due to interaction with moisture and oxygen in the air. The carbon-based organic material used to make these cells is prone to degradation under these conditions, making a protective layer necessary to ensure optimal performance.

“The metrics used to evaluate a new solar cell technology are typically limited to their power conversion efficiency and their cost in dollars-per-watt. Just as important is integrability — the ease with which the new technology can be adapted. The lightweight solar fabrics enable integrability, providing impetus for the current work. We strive to accelerate solar adoption, given the present urgent need to deploy new carbon-free sources of energy,” mentions Vladimir Bulović, the Fariborz Maseeh Chair in Emerging Technology, leader of the Organic and Nanostructured Electronics Laboratory (ONE Lab), director of MIT.nano, and senior author of a news paper describing the work.