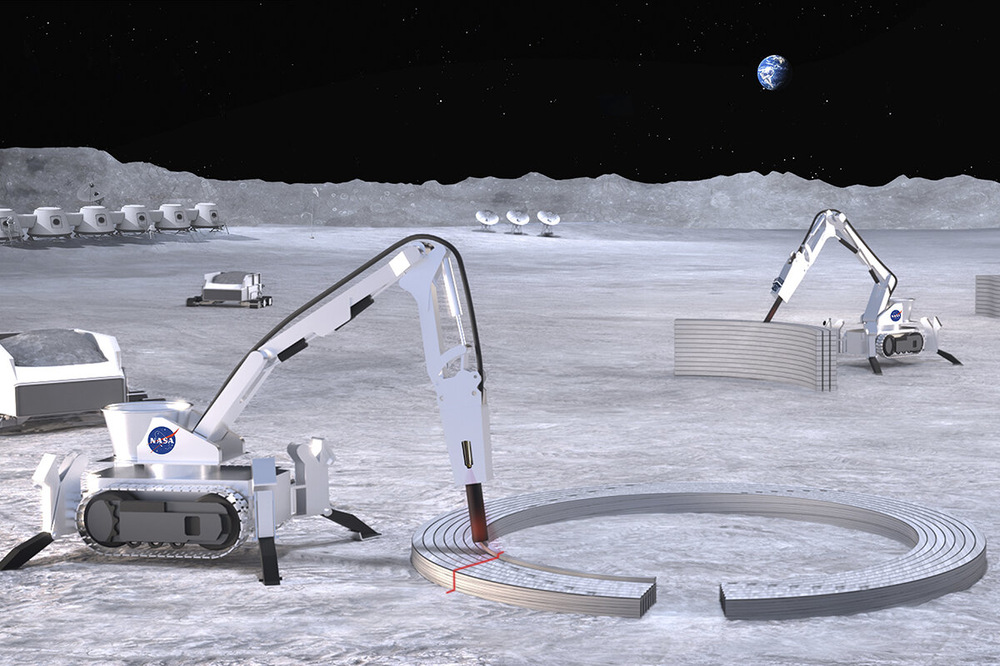

In the grand narrative of space exploration, a transformative chapter is being written – not in the stars, but in the labs and research centers of Earth. As NASA’s Artemis 3 mission prepares for a historic return to the Moon, researchers are focusing not just on getting there, but on staying there. The key lies in a groundbreaking material, poised to revolutionize space construction: 3D-printed sulfur-regolith concrete (SRC).

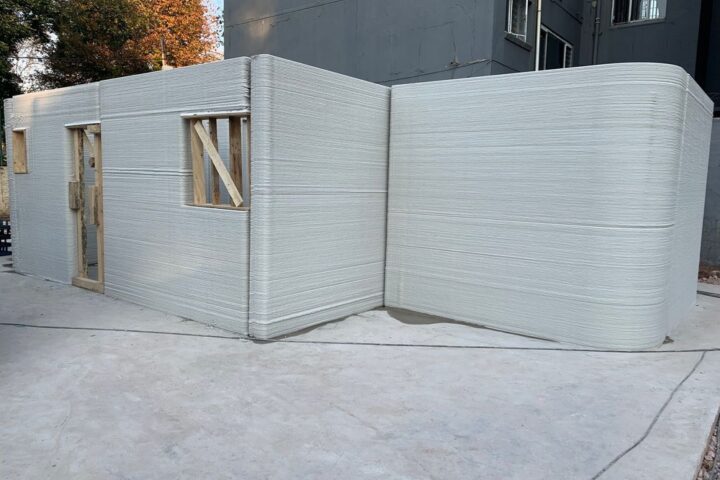

The collaboration between LSU’s Assistant Professor Ali Kazemian and NASA scientists Michael Fiske and Jennifer Edmunson is not merely academic; it’s a crucial step towards extraterrestrial habitation. Their research, funded by a $200,198 NSF grant, leverages lunar soil (regolith) and sulfur to create SRC. By eschewing water, a precious resource in space, for molten sulfur, they’re crafting a building material uniquely suited for lunar conditions. Kazemian elucidates, “Molten sulfur is the binder and regolith, i.e., Lunar soil, acts as the filler material.” This approach circumvents the prohibitive cost of transporting materials from Earth.

The process involves high-temperature SRC extrusion, studied at LSU, and space resilience tests under extreme conditions at NASA’s Marshall Space Flight Center. These tests assess SRC’s behavior against vacuum, temperature fluctuations, and micrometeorite impacts, ensuring its viability in harsh lunar environments.

Similar Posts

This research isn’t just about building on the Moon; it’s a testament to human ingenuity and adaptability. It underscores the importance of utilizing in-situ resources, a practice that could redefine not just space exploration, but also address earthly challenges like housing shortages and disaster relief. Kazemian notes, “Sulfur concrete has unique properties, such as superior mechanical strength and rapid hardening.”

The implications of SRC extend to Mars and beyond. With Mars missions on the horizon, the lessons learned from lunar construction will be invaluable. This interdisciplinary approach, combining geology, engineering, and space science, symbolizes a new era of collaborative innovation.

Behind the science is a story of human resilience and aspiration. From constructing lunar habitats to potentially alleviating global housing crises, this technology bridges the gap between celestial dreams and terrestrial necessities.

The research delves deep into the intricacies of SRC. Understanding the extrusion parameters and the interaction between material, process, and environmental factors is crucial. Kazemian and his team are not just creating a material; they’re crafting a solution tailored to the unique challenges of space.

As we edge closer to establishing a sustained presence on the Moon, and eventually Mars, technologies like SRC are not just helpful, they’re essential. The potential of 3D-printing large structures, like lunar habitats, at NASA Marshall is a glimpse into a future where space is not just a destination, but a home.