Scientists have made a groundbreaking discovery to speed up the annealing process in solar panel production to increase its commercial value. There could be a revolution in solar cell manufacturing & recycling by a groundbreaking discovery made by scientists from Macquarie University. To facilitate the annealing process in solar panel production, the discovery involves the use of a commercial microwave. A crucial step in solar panel manufacturing, annealing, typically involves heating the materials to temperatures above 500 degrees Celsius. By tradition, we use ovens for annealing, but a recent study shows that microwaves offer several advantages, including speed, energy, efficiency, & improved recyclability. Owing to their ability to target specific materials, microwaves selectively heat individual substances, such as Silicon.

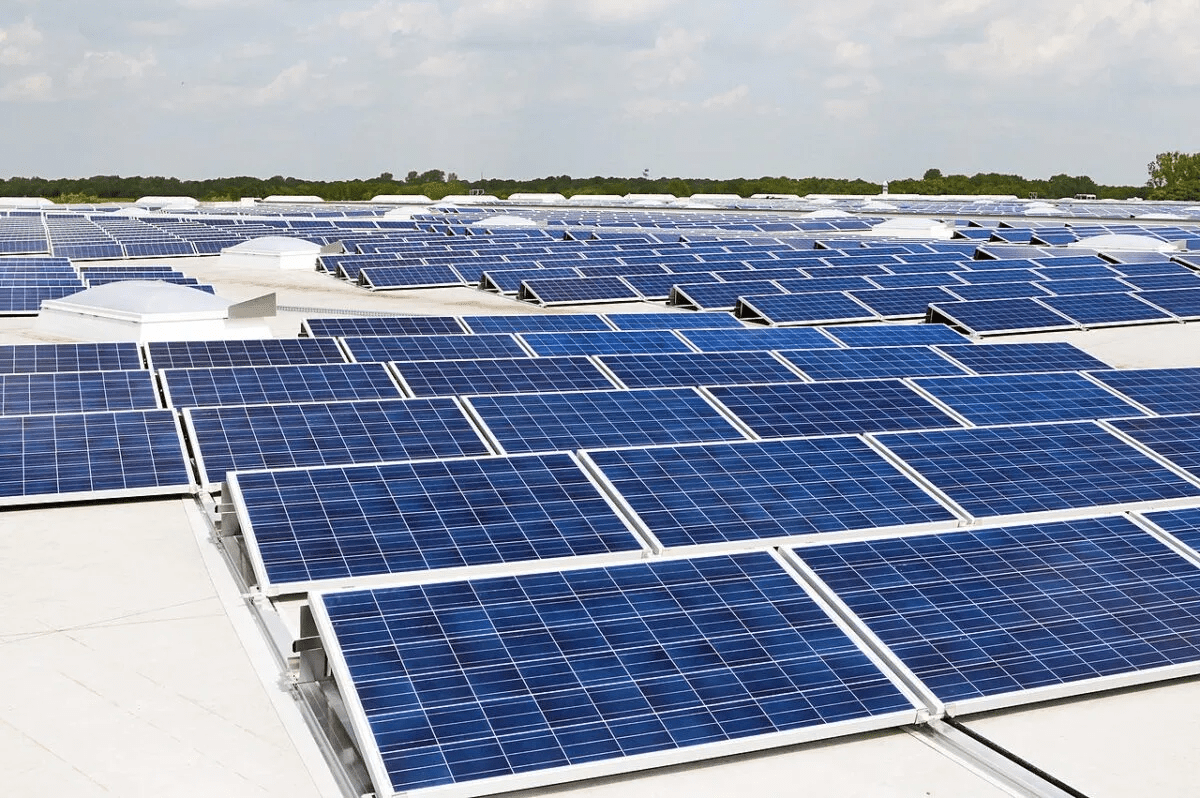

As a clean & emission-free renewable energy source, solar power has gained popularity. Solar power faces challenges regarding cost-efficiency & recycling methods, despite its environmental benefits. In order to address these challenges, the researchers in Sydney have potentially found a solution. With Silicon being the second most abundant material on Earth after oxygen, a solar panel comprises a layer of Silicon cells. To enhance flexibility & reduce hardness, the Silicon used in solar panels undergoes a highly processed annealing treatment.

The lead author from Macquarie University, Dr. Binsh Puthen Veettil, explains that the microwave selectively heats the thin layer of silicon, making the process extremely fast. Microwave annealing significantly reduces the contamination from the oven walls, as the heat flows primarily from the silicon outwards, unlike traditional ovens.

Currently recycling solar cells requires an energy-intensive process, including crushing the panels & heating them to temperatures over 1000 degrees Celcius to extract valuable elements. As demonstrated in the study, microwave annealing proves to be nearly as efficient as furnace annealing but offers time-saving & energy- efficient advantages.

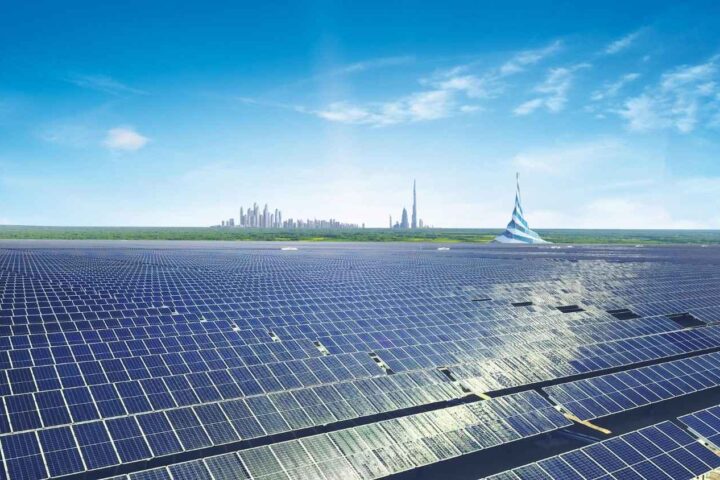

Facilitating easier disassembly & recycling, microwave radiation heats the Silicon while leaving the laminated panel of glass, aluminum, & plastic mostly unaffected. The plastic coating on the solar panel, softens, during treatment, enabling easy mechanical peeling. Without the need for harsh chemicals, this allows for the delamination of the scale & reuse of list components. Constituting a significant portion of the panel’s weight, the toughened glass can be preserved & reused by peeling off the Silicon cell. The glass component’s reusing could potentially make the recycling process economically viable.

Similar Posts

Microwave annealing requires lower temperatures & avoids the need for additional chemicals to dissolve & wash the plastic, unlike traditional methods. At present, the process is limited to laboratory-scale experiments & solar panels that fit within a commercial microwave. Actively exploring ways to improve & commercialize it, the researchers have filed a patent for the recycling process.

To scale up the microwave annealing technique, collaboration with industry partners & securing funding will be crucial. There is a need for the recycling process to be environmentally friendly & economically viable to encourage widespread adoption. Currently, solar panels are often discarded in landfills due to the lack of cost-effective recycling options.

Governments are now demanding proper recycling practices, as the first wave of solar panels installed decades ago nears the end of their life. Already microwave heating is widely used in industries such as rubber, wood,& ceramics for its economic efficiency, speed, & energy savings. Conducted in collaboration with the School of Photovoltaics at UNSW Sydney, the research received funding from the Australian Center for Advanced Photovoltaics & the Australian Government. The finding showcases the potential of microwave annealing for semiconductor devices, particularly in large-volume manufacturing processes like photovoltaic module production. Emphasizing the importance of sustainable solar panel recycling for a green future, the authors acknowledge the funding support from the Australian Renewable Energy Agency (ARENA).