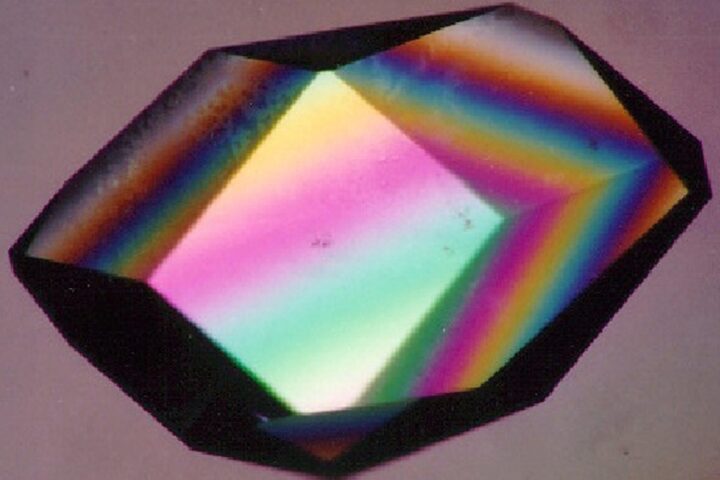

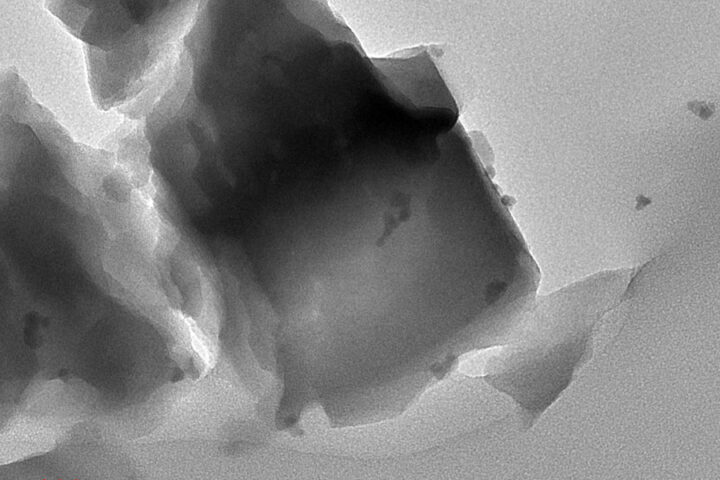

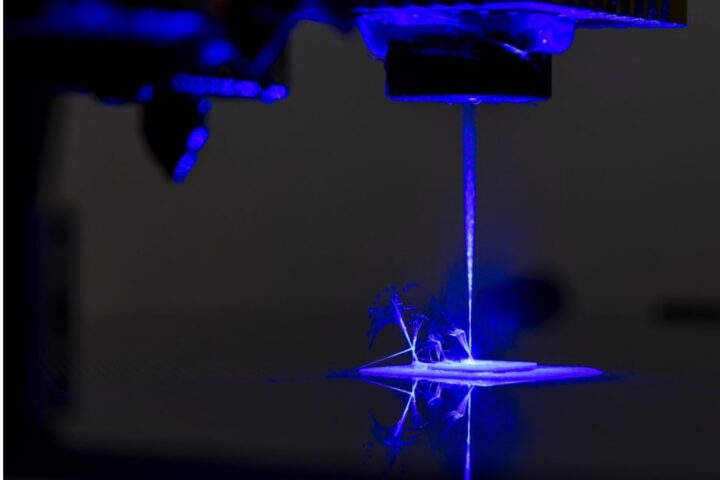

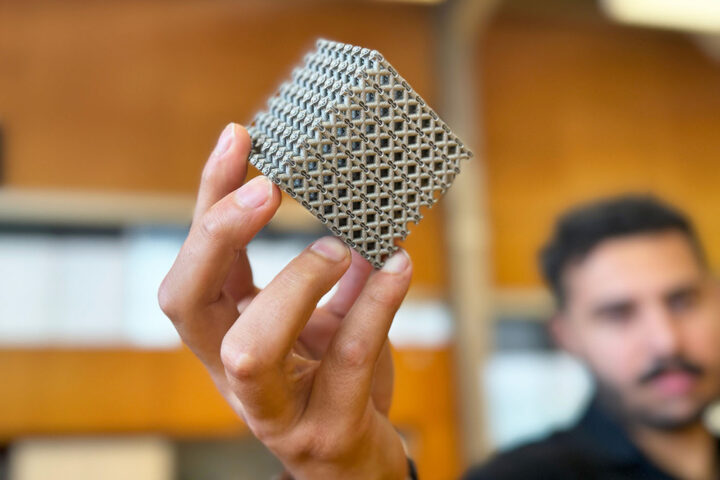

Graphene, a single-layer carbon atom sheet, has catapulted concrete technology into a new era. The University of Manchester, a hub for graphene innovation, in partnership with Nationwide Engineering, has developed Concretene. This material integrates graphene into concrete, resulting in a 30% strength enhancement over traditional RC30 concrete. This innovation means using less concrete for the same structural performance, significantly impacting cost and CO2 emission reductions.

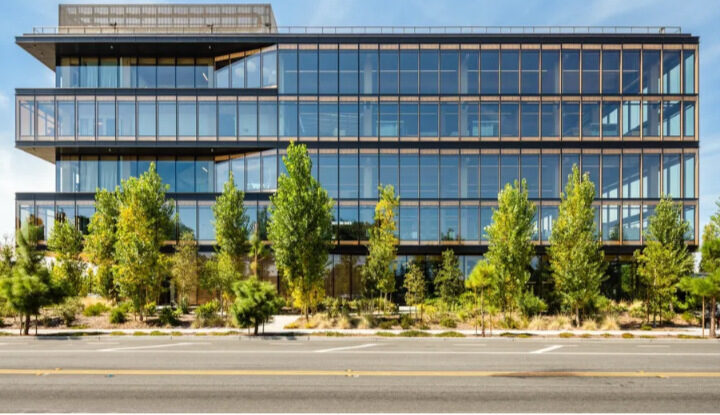

The potential of Concretene extends to large-scale industrial applications. Its first commercial use was in a 54×14-metre mezzanine floor at Mayfield, marking a pivotal step in its development as a widely-used building material. This installation was significant, as it was the first commercial use of Concretene in a suspended slab, a technique common in high-rise developments.

Similar Posts

Cement production, a key component of concrete, is a major contributor to global CO2 emissions, accounting for about 8% of worldwide emissions. Concretene addresses this by reducing the amount of concrete needed by up to 30% and cutting drying time. The use of graphene in concrete results in 6.3kg of CO2 per tonne of concrete, a significant reduction compared to traditional steel reinforcement. In one project, this equated to a CO2 reduction of 4,265kg.

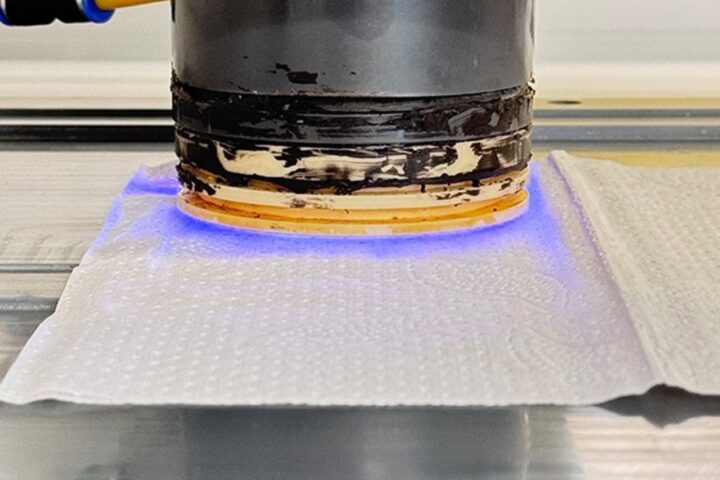

The journey from lab to real-world application has been rapid and successful. Concretene’s first pour in April 2021 at Southern Quarter gym in Amesbury was a milestone. This was followed by other significant projects, including a second pour at the GEIC and a large-scale project at Mayfield Depot. These developments highlight Concretene’s versatility and growing acceptance in the construction industry.

The scalability of Concretene is underpinned by its ease of use – it is added at batching plants like any other admixture, requiring no additional training or equipment. This commercial viability, coupled with its environmental benefits, positions Concretene as a key player in the sustainable construction movement. Its development has been supported by significant funding, indicating strong market confidence.