Sustainability is essential in every field, and footwear is no exception. Sneakers imagined by the Disassembly Lab feature 3D-knitted parts. They are repairable, restorable, replaceable, and recyclable. A lot of what makes this footwear great is clearly visible in its aesthetic itself. It makes one of those shoes your eyes fall in love with long before your feet do.

It’s easy to replace them with new ones without throwing away the entire sneakers. Robin said, “Disassembly is going to become a new legislative norm for the footwear industry. Products can’t live on their own anymore; they have to be conditioned to a new system if they want to become more responsible.” He added, “Essentially, Disassembly extends the life of a shoe, making it repairable, restorable, replaceable, and recyclable.”

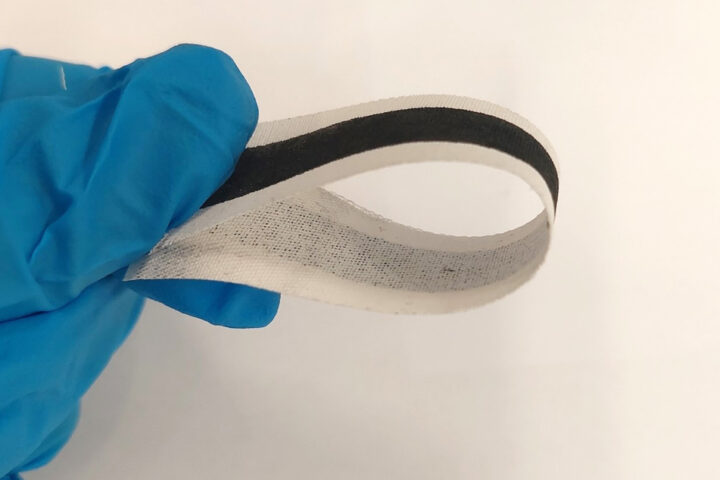

The glue is a major part of shoe assembly to hold components together. The upper part of a shoe is almost always glued to its outsole. It gives reliable durability. With their patterned ‘belts’ that can be adjusted, customized, and even tightened or loosened, the shoes look great. They are flexible. The pegs on the upper and lower halves can be shaped in circular or rectangular designs. Different patterns can be adopted with rubber bands. It is like sound waves (Sine, sawtooth, square, etc.).

Robin mentions in his project post on Instagram, “The aim is to rethink and redefine the way we build and assemble sneakers without glue. This research is inspired by various references and explores several distinct concepts. Each concept evolves over the course of the research, culminating in three shoes, offering a variety of functional and aesthetic solutions.” The Disassembly Lab is product designer Robin Luginbuhl’s Diploma Project in 2023. It was during his student tenure at the ECAL. It is a conceptual and formal study, so far.

Similar Posts

But Robin’s visual inquiry may have already been tried out in real life. For example, Zellerfeld’s washable 3D-printed shoes can be broken down. They can be remade. Similar sneakers are Noa Zaidman’s recyclable modular shoes. Diogo Pimenta’s three-part and modular sneakers are another similar product.

The thought process advanced by the Disassembly Lab that making repairable, replaceable, restorable, and recyclable shoes with 3D-knitted or printed parts are possible. The giants in the industry may want to look into integrating the system into their production system. As it can be assembled by hand, a small-scale industry too can adopt Robin’s pattern. Robin has presented many possibilities in the sneakers business.”These shoes, with their TPU soles and 3D knitted upper, are reduced to the essentials, enabling simple, rapid production and assembly by hand, and easy recyclability,” Robin concluded.