MIT engineers have developed a groundbreaking 3D printing method that tackles one of the industry’s biggest problems: waste from support structures. The new technique, announced on June 3, 2025, uses a special resin that responds differently to two types of light.

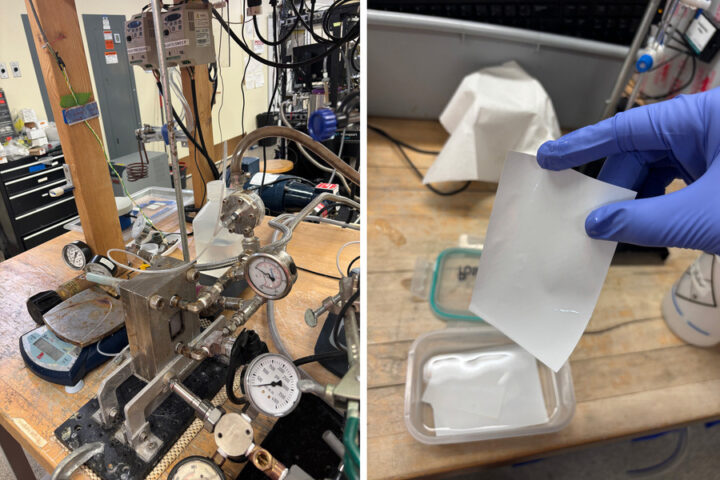

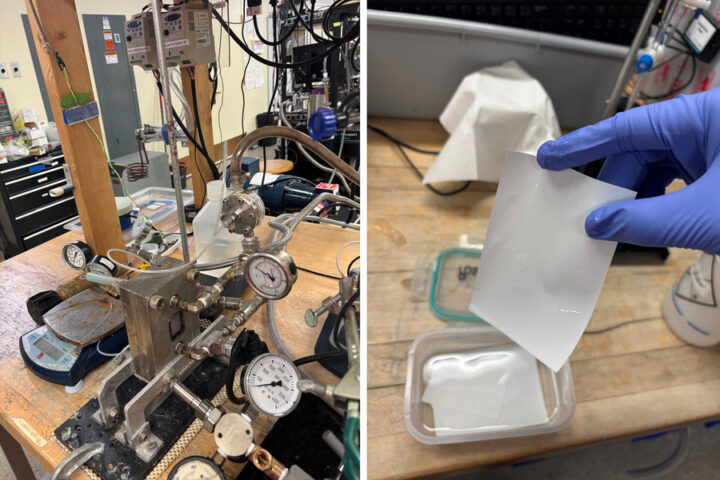

When exposed to ultraviolet (UV) light, the resin hardens into a tough, durable material. But when visible light shines on it, the same resin forms a solid that can be easily dissolved in common solvents. This dual-nature material allows for a much more efficient printing process.

“You can now print — in a single print — multipart, functional assemblies with moving or interlocking parts, and you can basically wash away the supports,” explains Nicholas Diaco, a graduate student involved in the research. “Instead of throwing out this material, you can recycle it on site and generate a lot less waste. That’s the ultimate hope.”

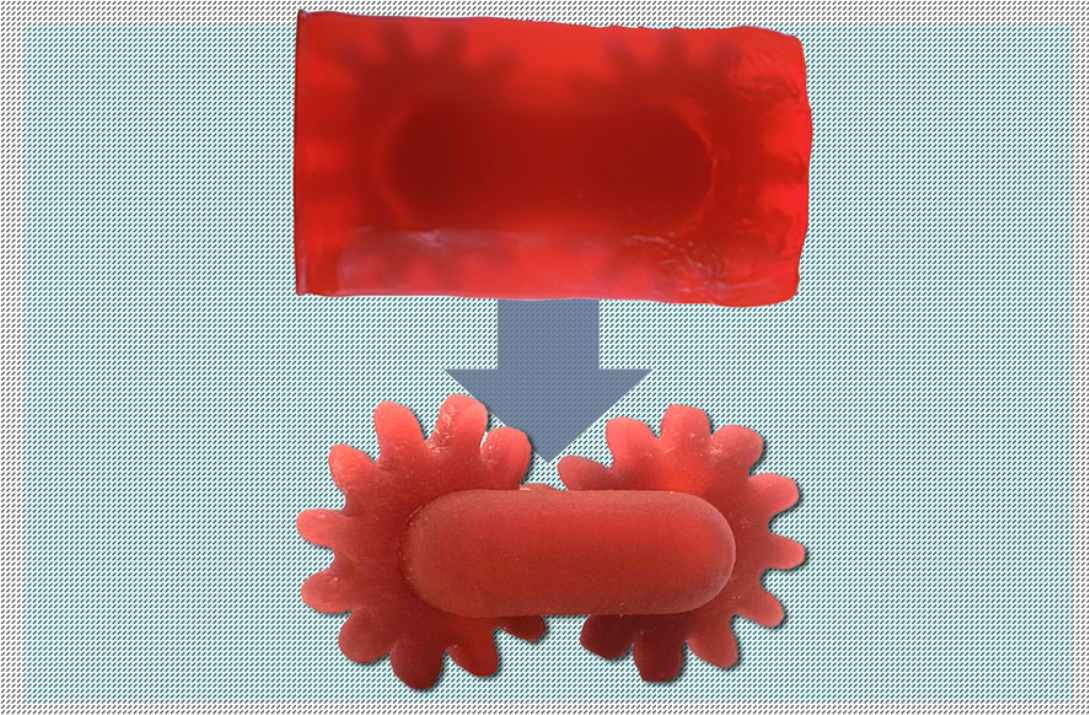

Traditional 3D printing requires support structures to hold complex designs in place during printing. These supports are typically removed by hand and thrown away after printing is complete. With MIT’s new method, the supports simply dissolve when dipped in solution, revealing the finished product without any manual work.

The dissolved support material can then be mixed back into fresh resin for future prints, creating a closed-loop recycling system. The supports can dissolve in various food-safe solutions, including baby oil, or even in the main liquid ingredient of the original resin.

To demonstrate this innovation, the team printed various complex structures, including functional gear trains, intricate lattices, a ball within a square frame, and a small dinosaur encased in an egg-shaped support that dissolved away when dipped in solution.

Similar Posts

The research team, which includes Professor A. John Hart, head of MIT’s Department of Mechanical Engineering, published their findings in Advanced Materials Technologies. Hart notes: “We’ll continue studying the limits of this process, and we want to develop additional resins with this wavelength-selective behavior and mechanical properties necessary for durable products.”

This innovation could significantly benefit industries that require intricate and personalized products, such as hearing aids, dental implants, and mouth guards. By eliminating waste and enabling the recycling of support material, the technique represents an important step toward more sustainable manufacturing practices.

The MIT breakthrough is part of a larger trend in 3D printing that focuses on reducing environmental impact while expanding design possibilities. As the technology continues to develop, it promises to make additive manufacturing more cost-effective and environmentally friendly.

This research was supported by the Center for Perceptual and Interactive Intelligence in Hong Kong, the U.S. National Science Foundation, the U.S. Office of Naval Research, and the U.S. Army Research Office.