According to a 2023 report published by the UN Environment Programme, “The buildings and construction sector is by far the largest emitter of greenhouse gases,” and debris from construction, demolition, and industrial processes is one of the biggest waste streams in the world. The Environmental Protection Agency US says “More than 75% of all construction waste from wood, drywall, bricks, and clay tiles ends up in landfills.

To deal with it, the world has begun exploration, and to eventually move towards nonstandard building materials, they have even started gaining significance.

Meet StoneCycling, a Netherlands-based start-up company that works to bring sustainability to the world of architecture through its innovative product line and techniques. Utilising upcycled and WasteBased construction materials to overcome the problem of scarcity. Their product line includes materials like CornWall, BioBased tiles or WasteBased bricks and slips.

StoneCycling is working on a mission to create beautiful building materials made from 100% upcycled waste, creating a positive impact on the planet. With the help of raw materials that are found everywhere in abundance and the potential of plants to replace synthetic-based products like plastics and resins.

( CornWall, WasteBased bricks and BioBased Tiles) Photo Source: StoneCycling

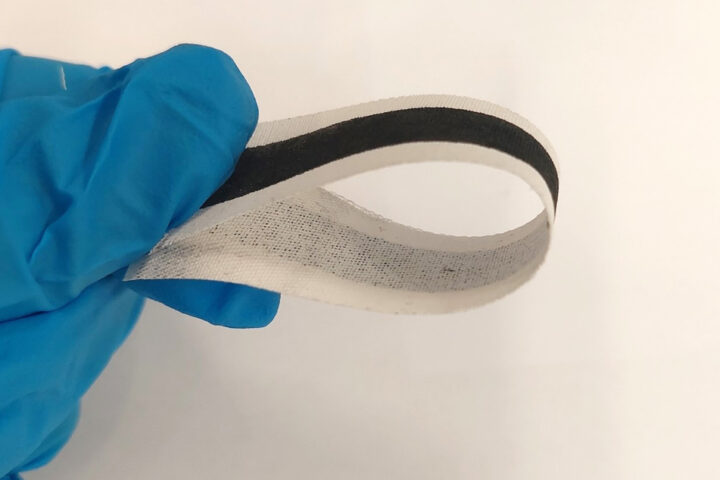

StoneCycling’s CornWall is a climate-positive, sustainable, and lightweight construction material focused on reuse and zero waste. Corn cobs are collected & dried after which they undergo a specific process of shredding that produces biomass which becomes the main ingredient for CornWall. It holds the capacity to store more CO₂ than is emitted during production over other cladding materials like UPVC which are synthetic polymers. Also, can be moulded into bespoken shapes and sizes making it suitable for building aesthetic interior walls and furniture. Comes under 8 different aesthetic shades yet the material price of CornWall is comparable to the price of a high-quality ceramic tile.

( CornWall, Texture, Swatches and Mood board) Photo Source: StoneCycling

The Annual Global consumption of corn amounted to over 45 billion bushels in the year 2022 – 23 according to statista.com. In 2018 the global generation of corn cob was approximately 144 million tons per year most of it was discarded or burnt. MDPI, in its report mentioned that about 164 Terra gram (Tg) corn cobs are globally produced each year. However, only about 8 million tons of corn cobs are used in various applications and the rest 82.6% are burned. Also, MDPI in its report on “crushed corn cob as a sand substitute for construction” stated how effective Corn ash admixture can be for the long-term strength development of concrete. Now evaluate, how much of it could be utilised?

(Corn Wall Impressions in Shade, Burgundy, Mustard, Dark Blue, Warm Beige, Terracotta, Light Green & Light Blue) Photo Source: StoneCycling

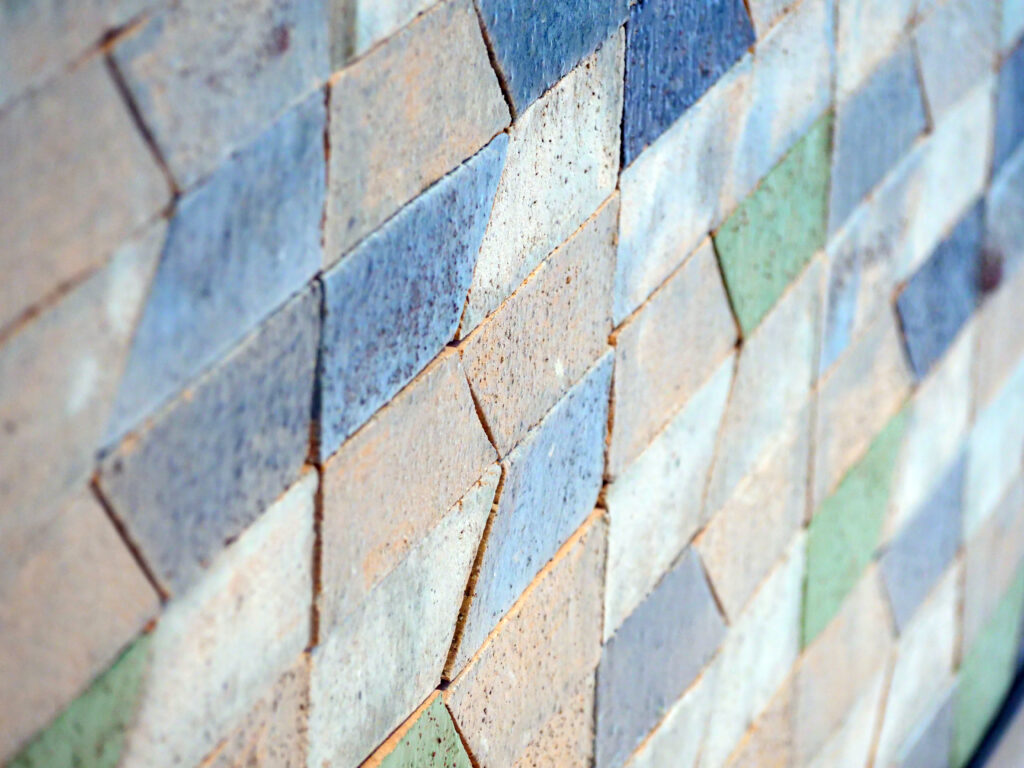

StoneCycling WasteBased bricks and tiles are made of Debris collected from construction and demolition sites. Carefully selecting, the appropriate waste suitable to work with is separated and ground into the right size, sorting these and long processes of development eventually result in products both safe to use and of the highest quality. Which provides a subtle and classy look.

Talking about India, it currently holds the 6th position with 34.30 million tons in global maize production. On the other hand, Construction and demolition waste is a major environmental concern in India, the Construction waste generated here is 150 MT and accounts for 35%–40% of the global C&D waste annually. Out of which India recycles only 1% of the C&D waste that is produced, according to the Centre for Science and Environment estimates. Despite the regulations and schemes implementation of C&D waste management is difficult. What do you think? In this case, will the idea started by StoneCycling work in its favour? Or other factors like overpopulation, and extreme climatic conditions might never let it happen?

( Waste Based bricks, Bio Based Tiles and Bio Based slips) Photo Source: StoneCycling

In 2013, Science Direct highlighted the “Production of bricks from waste materials” in its article. Similarly, various studies suggest switching from clay to WasteBased bricks To reduce the wastage of raw materials. Have inspired commercial and residential building owners from all over the world to opt for waste-based construction materials.

Similar Posts

Whether talking about a chancery house in London or Nando’s reading gateway. Ace & Tate an eyewear outlet in Spain, building a project like UMAR in Switzerland or the mushroom wall design of the COS store in Luxembourg. StoneCycling has left a massive global impact on architecture with its sustainable and luxurious Looking projects.