At the University of Michigan, the BioMatters team, under the Taubman College of Architecture and Urban Planning and DART Laboratory, is addressing a significant environmental issue. They’ve developed a unique material from upcycled sawdust that is biodegradable, reusable, and recyclable. This material is innovative and opens up new possibilities in the realm of concrete construction.

Globally, sawdust is a massive byproduct of the wood industry, with around 15 billion trees cut each year. In the U.S., 2.1% of the 2022 total annual energy consumption came from wood waste, including sawdust. But, sawdust disposal poses environmental risks, like water toxicity and harm to aquatic life. Dr. Sheldon Duff, a professor at the University of British Columbia, highlights the issue: “The decomposition of a tree in a forest is similar to the impact of sawdust, but the difference is of scale… when you’re processing a whole large volume of wood and large concentrations of these materials get out into the runoff, they cause toxicity and are toxic to a broad range of organisms.”

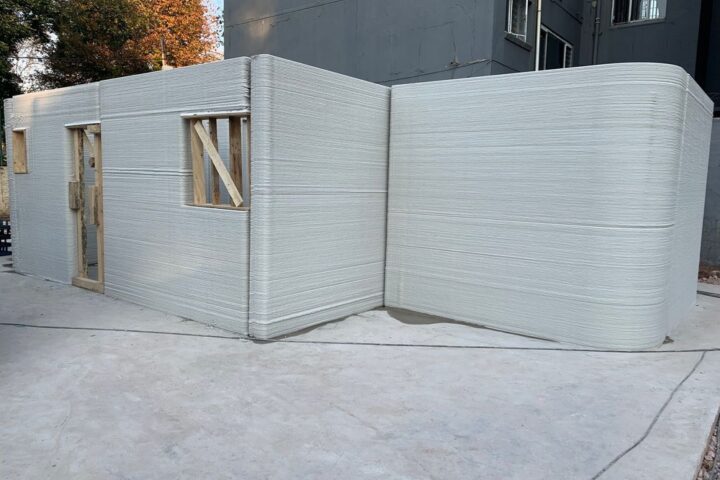

The innovative approach at the University of Michigan involves a blend of robotic 3D printing and concrete casting. This process, led by Mania Aghaei Meibodi and her team, including Muhammad Dayyem Khan, Tharanesh Varadharajan, and Zachary Keller, creates zero-waste concrete structures. Unlike other sawdust-based solutions using petroleum-based polymers, this material uses biopolymers, making it fully decomposable.

Similar Posts

Here’s how it works: The 3D-printed wood formwork shapes the concrete. After curing, this formwork is recycled by grinding and rehydrating, almost eliminating waste. This approach significantly cuts down on the pollution and costs associated with traditional concrete formwork.

Muhammad Dayyem Khan explains, “Rather than burning [sawdust] and generating more CO2 emissions, it is so much better that we make it into a material that is actually capable of being used again and again.”

This development at the University of Michigan is a major stride towards sustainable construction. It turns a wood industry byproduct into a valuable resource for the concrete industry, aligning with the urgent need for sustainable urban development practices. This project exemplifies the potential of innovative, sustainable solutions in tackling environmental challenges in construction.