Efficiency in hydrogen production by electrolysis is about 70 to 80 percent. Experts from a start-up have significantly increased efficiency through optimization. Researchers at the University of Wollongong (UOW) have developed a highly efficient technique for hydrogen production that achieves an efficiency of 98 percent under laboratory conditions, according to a publication in the journal Nature Communications. The research project has since led to the creation of the start-up Hysata, which is implementing the highly efficient method on an industrial scale.

According to the company, between 20 and 30 percent of the energy is lost during the production of hydrogen through electrolysis, a process where water is split using electrical energy. Thus, about 52.5 kWh of electricity is needed to produce one kilogram of hydrogen, which contains 39.4 kWh of energy. However, the start-up’s highly efficient method requires only 41.5 kWh of electricity for large-scale plants, corresponding to an efficiency of 95 percent.

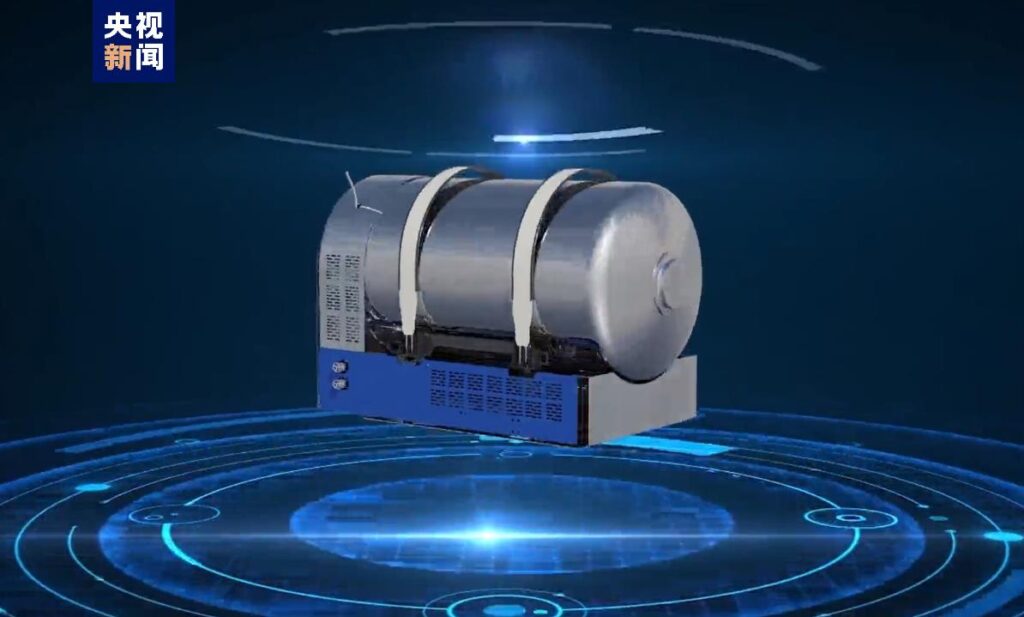

The high efficiency is achieved through so-called capillary-fed electrolyzers, where significantly fewer bubbles form in the electrolysis cell. In capillary-fed electrolyzers, water is continuously drawn from the bottom by capillary action and reaches the electrodes through thin capillary tubes. Therefore, the electrodes do not have to stand directly in the water reservoir. Additionally, the capillary method allows the hydrogen and oxygen produced to escape the system more easily, whereas in conventional electrolysis devices, the gases often accumulate on the electrodes, reducing their efficiency.

According to a press release from Hysata, investors recently provided the company with 111 million US dollars, which will be used to further develop the technology and expand production capacities. A significant issue in hydrogen production by electrolysis is energy loss, as a considerable amount of energy is lost before the hydrogen can be used as an energy source.

Similar Posts

Hysata relies on capillary-fed electrolyzers, which are said to be significantly cheaper compared to conventional setups, as the start-up explains. The entire process is also less complex because fewer pumps are needed. During capillary-fed electrolysis, fewer bubbles are formed, making the process much more efficient. In capillary electrolysis, water is continuously drawn from the bottom of the cell by capillary action. The water is transported to the electrodes through ultra-thin capillaries, so the electrodes no longer need to stand directly in the water. Another advantage is that the two gases – hydrogen and oxygen – can escape easily through the capillary method. If the electrodes were in the water, gas bubbles would form on them, hindering access to the electrodes. This is not the case with Hysata’s approach. This increases efficiency and reduces costs.