A new £14 million research center in the UK will use tiny organisms to transform factory waste into useful products like medicines and cosmetics. The Carbon-Loop Sustainable Biomanufacturing Hub (C-Loop) aims to create a cleaner manufacturing system that reuses materials instead of sending them to landfills.

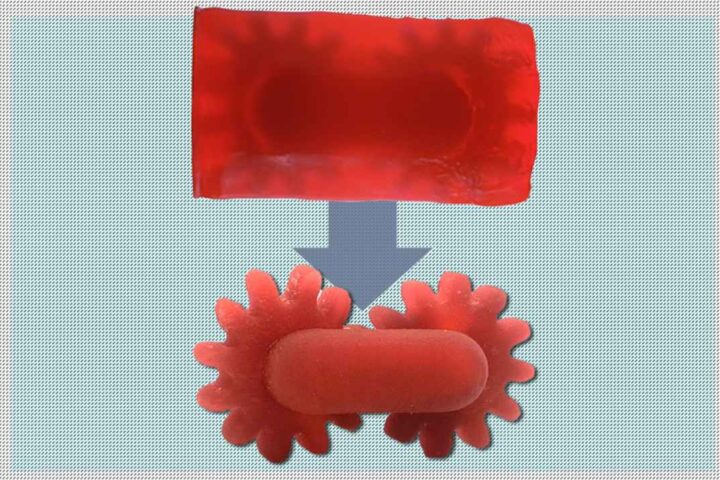

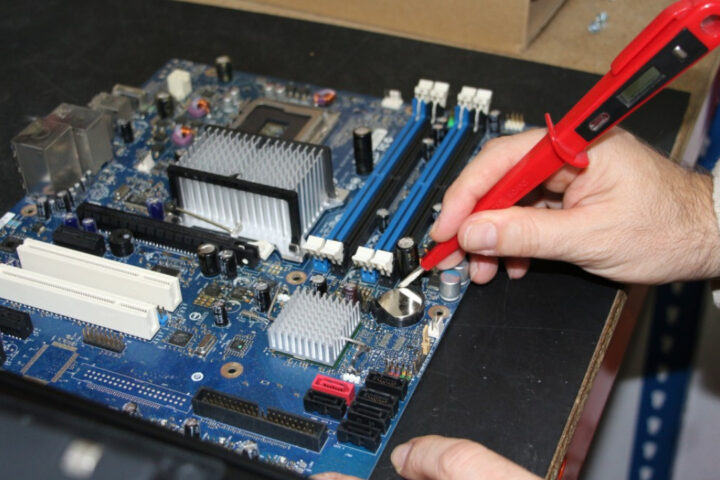

Currently, over 90% of everyday products in the UK are made using fossil fuels and unsustainable chemical processes. The C-Loop hub plans to change this by using specially engineered microorganisms – microscopic living cells – to convert carbon-rich industrial waste into valuable materials.

“Amid a growing population, diminishing natural resources, and a changing climate, there is now an urgent environmental, industrial and political imperative to rapidly harness engineering biology technologies to defossilise manufacturing and accelerate the UK’s path to net-zero,” said Professor Stephen Wallace, Director of C-Loop and Chair of Chemical Biotechnology at the University of Edinburgh.

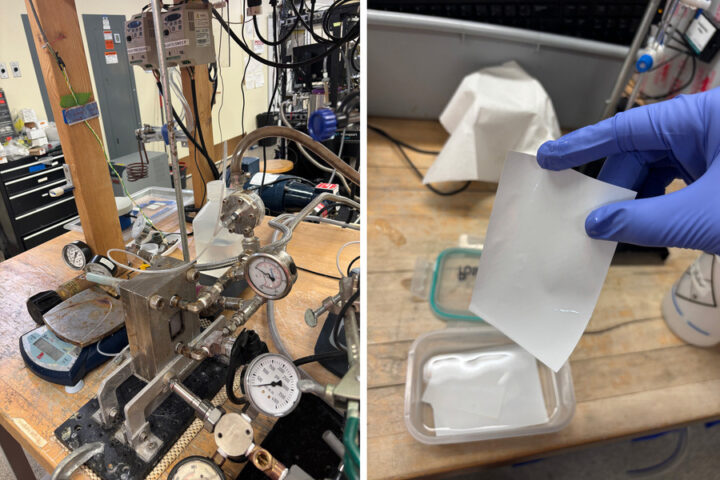

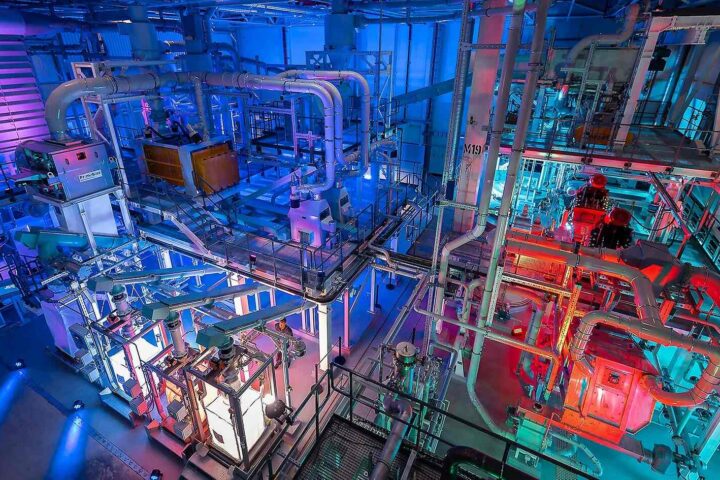

The project will establish the UK’s first “BioFactory,” a dedicated facility for analyzing waste, evaluating sustainability, and scaling up promising technologies. This facility will help reduce emissions, keep materials out of landfills, and build a manufacturing system that doesn’t rely on fossil fuels.

The Engineering and Physical Sciences Research Council (EPSRC), part of UK Research and Innovation (UKRI), is providing £11 million of the funding. The hub will be led by the University of Edinburgh in partnership with the Universities of Manchester, Nottingham, Surrey, University College London, and Imperial College London.

More than 40 industry partners are involved, including global companies from seven different sectors and national innovation centers like IBioIC. The project brings together microbiologists, chemists, engineers, and sustainability experts to develop new supply chains and speed up the adoption of these green technologies.

Similar Posts

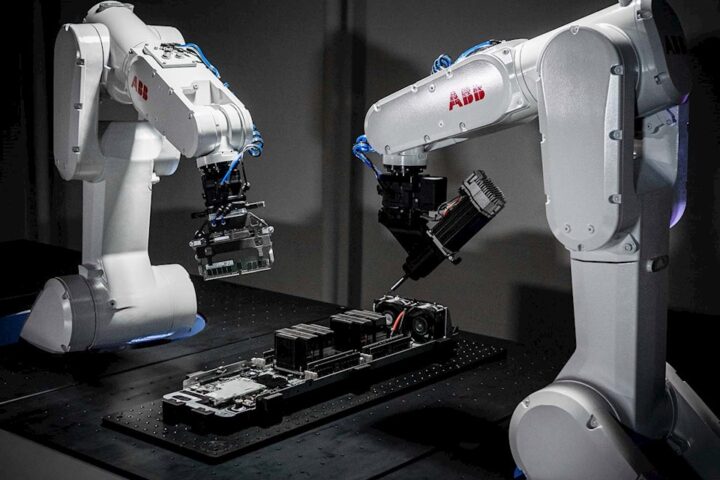

The University of Surrey will focus on creating smarter manufacturing systems. Professor Jhuma Sadhukhan from Surrey explained their approach: “C-Loop is our moonshot to turn sustainability from a compliance checkbox into a design driver.” Their team will use artificial intelligence to map and improve every stage of the manufacturing process, creating a digital model that enables real-time optimization.

Dr. Jen Vanderhoven, Chief Operating Officer at BBIA and Chair of the C-Loop Board, emphasized the urgency of the project: “There’s no time to waste in getting to no waste – this project not only tackles major environmental challenges but also unlocks significant economic opportunities through the production of sustainable chemicals.”

This hub represents a key part of the UK’s strategy to reshape manufacturing for a greener future. Professor Charlotte Deane, Executive Chair of EPSRC, noted: “These hubs will play a vital role in reshaping manufacturing to help the UK achieve green growth. By combining deep research expertise with real-world partnerships, they will develop the technologies, tools and systems we need for clean, competitive and resilient industries.”

C-Loop is one of four new engineering biology hubs funded by EPSRC, with each focusing on different aspects of sustainable manufacturing. The University of Edinburgh, which leads this initiative, hosts the UK’s largest group of researchers in engineering biology and works with more than 200 related companies to drive innovation.

The project aligns with the UK government’s identification of engineering biology as one of its five priority areas. By converting waste that would otherwise end up in landfills into valuable products, the hub aims to create high-value jobs while significantly reducing the environmental impact of manufacturing.