These fungi-based building tiles mimic elephant skin to cool structures naturally, cutting energy use and offering a sustainable alternative to synthetic materials.

How Mushroom Tiles Keep Buildings Cool

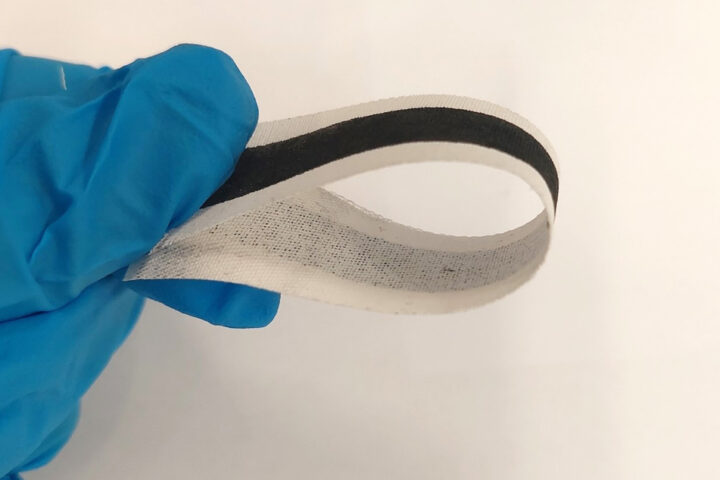

Scientists at Singapore’s Nanyang Technological University (NTU) and bioSEA have developed hexagonal “fungi tiles” made from oyster mushroom mycelium and bamboo shavings. These tiles feature a wrinkled texture inspired by elephant skin that helps regulate temperature by slowing heat absorption (5.01 °C/min versus 5.85 °C/min on a hot plate) and boosting cooling by 25% in dry conditions and 70% in wet conditions. The wrinkles increase surface area while the material’s hydrophobic “fungal skin” holds water droplets for evaporative cooling. The research appears in the February 2025 issue of the Energy & Buildings journal, confirming the scientific credibility of this innovation.

Beyond Basic Benefits

These tiles offer more than just cooling. The mycelium composites are fully biodegradable, comprised of about 95% plant material and 5% fungal biomass. Unlike synthetic insulation that persists for centuries, these tiles break down completely within months under standard composting conditions, returning nutrients to soil and supporting circular material use.

Mycelium composites typically show compressive strengths between 0.25 and 1.9 MPa, similar to light foams but less than concrete. While specific fire safety data for these textured tiles is still being collected, similar mycelium panels have achieved Class B fire ratings (flame spread under 75) with charring rather than flaming behavior.

Production and Costs

The manufacturing process involves growing mycelium for 3–4 weeks (two weeks in-mold, two weeks post-mold), followed by three days of drying at 48 °C. This uses minimal energy, requiring only ambient dark conditions for growth and low-temperature drying.

While NTU hasn’t published exact costs, comparable studies estimate production at USD 10–15 per square meter for small batches, with potential 30–50 % cost reductions through process optimization and improved mycelium strains. The university is working with startup Mykílio to scale up mold sizes and speed up incubation.

Building Code Compatibility

The thermal properties of these fungi tiles rival or improve upon conventional materials like glass wool and extruded polystyrene, meeting Singapore’s Building and Construction Authority (BCA) Green Mark criteria for façade insulation. NTU’s campus—already certified 100 % Green Mark Platinum—provides an ideal testing ground for pilot installations that could earn innovation credits under both LEED and BCA Green Mark frameworks.

Learning from Nature’s Design

This approach builds on established biomimicry precedents. Zimbabwe’s Eastgate Centre (1996) uses termite–mound–inspired ventilation that reduces energy consumption by up to 90 % compared to conventional systems, saving 35 % on total energy and 10 % on capital costs. NTU’s work extends this tradition by translating elephant skin microstructures into building materials.

Design Possibilities

Beyond their technical performance, these tiles offer aesthetic versatility. Mycelium readily takes both form and color from its molds and can be pigmented with natural dyes like turmeric or charcoal. Their hexagonal shape allows for varied installation patterns on both exterior and interior surfaces—ideal for a range of sustainable building materials applications.

Expert Assessment

Associate Professor Hortense Le Ferrand of NTU notes: “Mycelium-bound composites could be a promising alternative… biodegradable, porous, and thermally on par with synthetics.”

Independent reviews (e.g., “Advanced Materials From Fungal Mycelium,” Scientific Reports 2017) highlight additional benefits of mycelium composites, including low embodied energy, carbon sequestration potential, and sound absorption properties.

This fungi-based technology represents a practical step toward buildings that regulate temperature more naturally while reducing waste and energy consumption—a compelling example of how observing nature’s solutions can reshape our built environment.