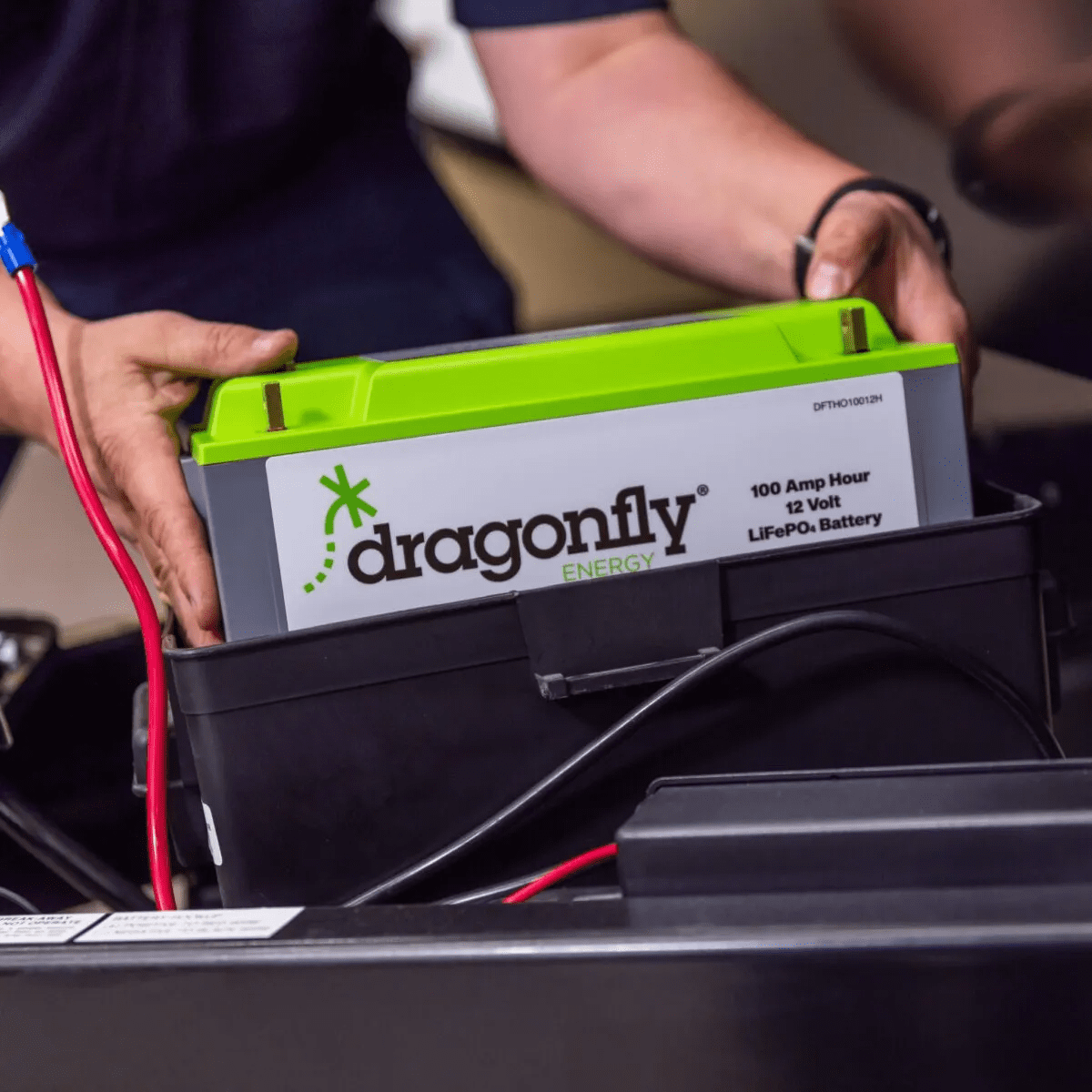

After the successful completion of Dragonfly Energy’s U.S. lithium battery cell pilot line, an innovative energy storage company, a significant turning point was reached in the nation’s battery cell manufacturing capabilities. The company takes pride in designing and assembling its batteries in the United States, supported by a team of experienced scientists.

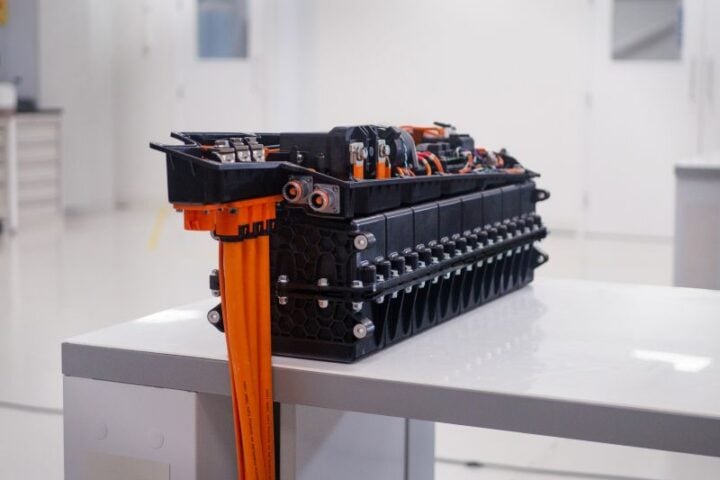

During a recent tour and conversation with NNBW at Dragonfly Energy’s South Meadows operations, CEO Dr. Denis Phares revealed that they are deploying a new manufacturing process they invented. This new process allows them to create a unique form of cell with a solid-state electrolyte, making it non-flammable and differentiating it from traditional cells. It opens up new possibilities for their business.

Phares also highlighted the use of large hoover dryers in conventional battery cell production sites to reclaim unpleasant solvents, a step that their exclusive dry deposition manufacturing methods do not require.

Dragonfly Energy’s pilot line showcases the scalability of their patented dry deposition manufacturing methods, making their batteries an excellent replacement for lead-acid batteries across various markets, including RVs, marine vessels, residential, backup storage, and large-scale industrial applications.

This accomplishment demonstrates that Dragonfly Energy’s innovative manufacturing processes can support mass production, thereby paving the way for a domestic lithium-ion battery supply chain. Their battery cell manufacturing methods are highly chemistry agnostic, allowing for potential future market expansion.

The company’s methods offer several advantages, including a significantly smaller production footprint and the elimination of harmful solvents used in conventional cell manufacturing. Their production process is expected to have a lower environmental impact, utilizing less energy and requiring fewer resources.

With the addition of another production line, the pilot line can produce up to 150MWh of domestically manufactured LiFePO4 battery cells annually, making it an efficient and space-saving operation.

Dragonfly Energy has plans to start manufacturing cathodes in the third quarter of 2023, aiming to finish cells by the year-end. Their goal is to reduce reliance on foreign cell suppliers and achieve full cell production entirely in America by the final quarter of 2023.

The ability to manufacture battery cells domestically aligns with Dragonfly Energy’s objectives of establishing a closed domestic supply chain and reducing the levelized cost of energy storage. The successful scale-up of their dry deposition procedure allows them to explore new markets and advance solid-state battery technology.

The company envisions vertical integration of battery production and strengthening their brand by incorporating American-made battery cells into their Battle Born Batteries™ products. The completion of the pilot line after successful anode material production marks a significant turning point in their expansion into cell manufacturing.

With a focus on local manufacturing of non-flammable solid-state battery cells, Dragonfly Energy holds a prominent position in the growing energy storage sector. Their expertise in lithium-ion battery technology and commitment to research and development drive industry development and foster creative thinking.

Dragonfly Energy’s proprietary dry powder coating technique offers a more economical and environmentally friendly approach to battery cell manufacturing, meeting the rising demand for energy storage solutions and improving production efficiency.

The construction of the entire pilot line reflects Dragonfly’s commitment to raising industry standards in battery power technology. As they expand into manufacturing solar cells, the company contributes to developing a more reliable and sustainable smart grid infrastructure.

The completion of the pilot line allows Dragonfly Energy to provide prototypes of its American-made battery cells to potential clients, accelerating their commercialization. Their record of growth and a strong customer base positions them as a trustworthy vendor of US-built battery cells, enabling them to expand market share.

Similar Post

The company’s focus on improving battery innovation, performance, and sustainability aligns with the evolving requirements of the clean energy and electric car markets. Their ability to create more efficient, secure, and long-lasting battery solutions gives them a competitive edge in the industry.

Through their commitment to research and development and a large patent portfolio, Dragonfly Energy solidifies its position as a market leader in deep cycle lithium-ion batteries. The development of the pilot line and successful anode material production exemplify their dedication to changing the future of battery production and energy storage.

With ongoing technological advancements and manufacturing methods, Dragonfly Energy is well-positioned to accelerate the shift towards a sustainable and energy-independent future.