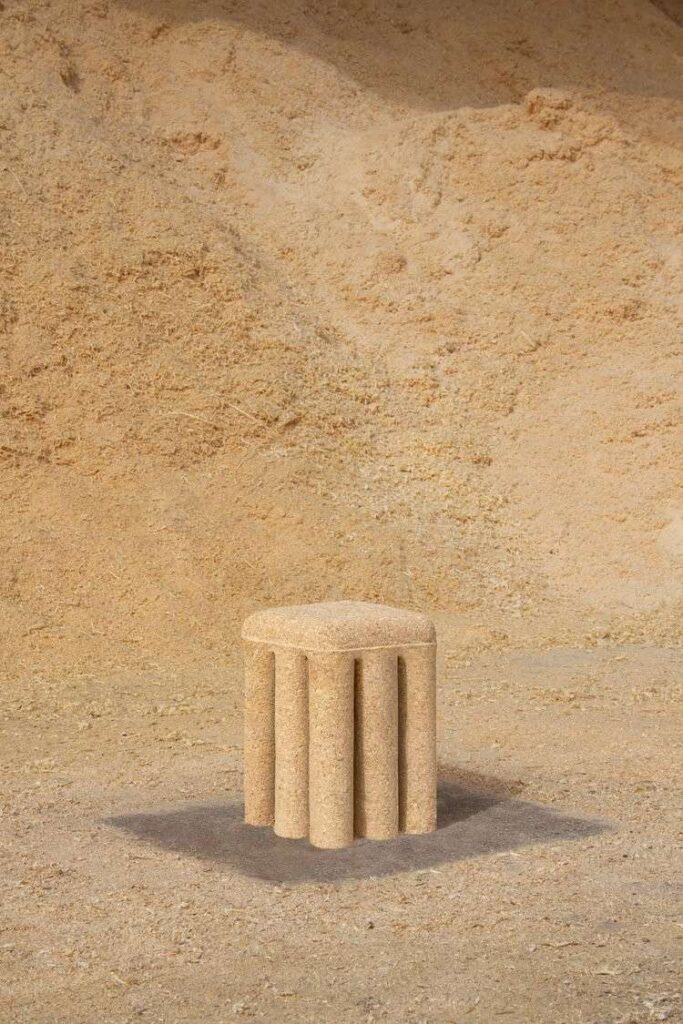

Every year, sawmills across Europe generate mountains of sawdust that often ends up burned or buried in landfills. What if this waste could become something useful before returning to the earth? That’s exactly what the Briket stool accomplishes – a fully recyclable piece of furniture made entirely from compressed sawdust and potato scraps.

The Briket stool, designed by Swiss creator Renaud Defrancesco with assistance from Anne Bertoncini, transforms two waste streams into a functional, sustainable object. After approximately 30 compression tests to ensure durability, this innovative design made its debut at Salone del Mobile 2024 in Milan as part of the “OUT OF THE WOODWORKS” exhibition at the House of Switzerland, organized by Geneva gallery NOV and Pro Helvetia.

A Solution to Massive Waste Streams

The numbers behind wood waste are staggering. According to research, EU member states (including Switzerland) produce roughly 60 million tonnes of wood waste annually, with approximately 44-46% being recycled based on recent Eurostat data. Meanwhile, the EU discards about 88 million tonnes of food waste each year, with potatoes contributing a significant portion of industrial by-products in the form of peels and pulp.

“We wanted to address both these waste streams simultaneously,” explains Defrancesco. “By combining sawdust that would otherwise be discarded with potato starch that acts as a natural binder, we’ve created a sturdy, functional object that requires no added chemicals or metal components.”

Similar Posts

How Potatoes Hold It All Together

The science behind Briket is surprisingly simple yet effective. The starch naturally present in potatoes (about 15% by weight) acts as a binding agent when mixed with sawdust and compressed under pressure. Scientific studies show that blending potato pulp with sawdust in a 1:2 ratio can create a composite with compressive strength of 3-5 MPa – sufficient for everyday seating – when pressed at 10-15 MPa and cured properly.

For optimal results, the manufacturing process requires kiln-dried sawdust with less than 10% moisture content and particles smaller than 3mm. This mixture is then pressed for approximately 2 minutes per component and either air-dried for 24 hours or cured in a 60°C oven for 6 hours to achieve full binding strength.

Nine Legs for a “Slow Disassembly” Experience

What truly sets the Briket stool apart is its unique nine-leg design. Rather than creating a traditional four-legged stool, Defrancesco opted for nine legs arranged in a way that allows for sequential removal.

“You can gradually remove the inner legs while the stool remains functional,” notes Defrancesco. “This creates a ‘slow disassembly’ experience that makes users more conscious of the lifecycle of their furniture.”

Eventually, when the stool reaches the end of its useful life, the remaining components can be burned as firewood. Based on standard calculations for wood products, each leg could potentially yield heat energy comparable to wood pellets when burned – turning what was once waste into useful thermal energy.

Local Production Potential

One of the most practical aspects of the Briket stool is its potential for local, small-scale production. Since sawdust is generated on-site at sawmills and carpentry shops, these facilities could potentially produce Briket stools with minimal transportation costs or carbon footprint.

The required equipment is relatively straightforward: a hydraulic or screw press capable of 10-15 MPa pressure, basic safety equipment including masks for dust protection, and a drying area. This approach aligns with the EU’s Circular Economy Action Plan, which sets a target of 75% packaging recycling (including wood) by 2030.

Research and Development

Researchers are exploring variations on the potato-binder concept. Scientific literature indicates that trials mixing potato binder with other agricultural residues, such as sunflower husks, could potentially broaden the material applications beyond just sawdust.

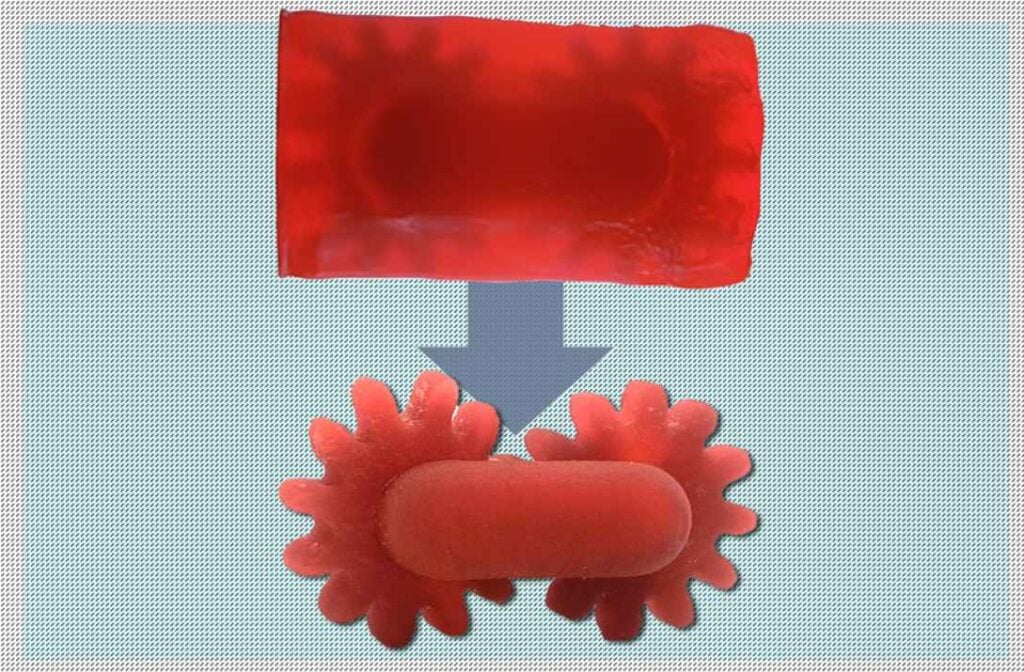

This research builds on earlier bio-composite experiments, such as those by Ecovative in the United States, which used mycelium (fungal growth) to bind sawdust into furniture prototypes around 2008. Briket’s approach offers an advantage in production speed by using potato starch instead of waiting for fungal growth, which can take weeks.

A Practical Approach to Sustainability

The Briket stool offers a tangible example of circular design principles in action. It starts with two waste materials – sawdust that would likely be burned and potato scraps that might be composted. These are combined into a functional object that serves as furniture for its lifespan. When no longer needed, it returns to the resource cycle as biomass fuel, generating heat without leaving behind non-biodegradable waste.

Unlike conventional particle board, which typically contains formaldehyde resins, Briket contains no chemical additives. And unlike many “eco-friendly” designs that require specialized facilities or processes, Briket’s production method is simple enough to be implemented in small workshops with basic equipment.

The stool was created using materials and processes that exemplify sustainable design practices. The design addresses a real environmental challenge while creating a useful product with minimal environmental impact. It demonstrates that with thoughtful design, waste materials can be transformed into valuable objects before ultimately returning to the earth.