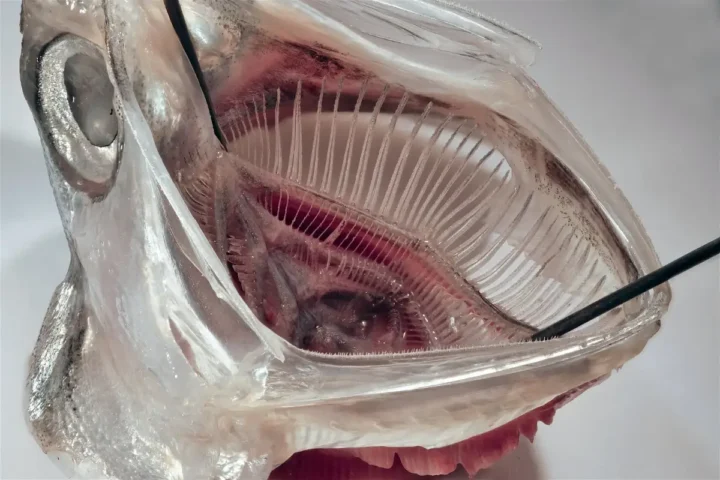

The researchers have developed an AI machine learning model to create a new variant of an enzyme that can degrade plastics in hours or days, when it typically takes centuries. The novel enzyme FAST PETase can deteriorate harmful plastics typically found in landfills.

12% of the world’s waste is contributed by PET, which is found in most consumer packaging. The enzyme breaks down plastics into smaller parts, which can then be reused, allowing for large-scale recycling in the industrial sector. Working at temperatures below 50 degrees Celsius, Fast PETase is affordable, portable, and efficient enough to be applied extensively.

Previous attempts at developing effective enzymes were challenged by slow reaction rates, limited temperature ranges, and pH levels. The discovery will contribute to the recovery and reuse of plastics on a molecular level.

Hal Alper, Professor of Chemical Engineering at the University of Texas, Austin, believes the possibilities for sustainable enzyme approaches are endless. Using AI,chemical engineering, and synthetic biology, a natural enzyme called PETase was turned into a plastic-eating Maxine by the team.

Short for polyethylene terephthalate, PET is a clear, strong, and lightweight plastic widely used in food packaging and plastic bottles. The new enzyme, called FAST PETase, can deconstruct PET plastic even more quickly and at low temperatures.

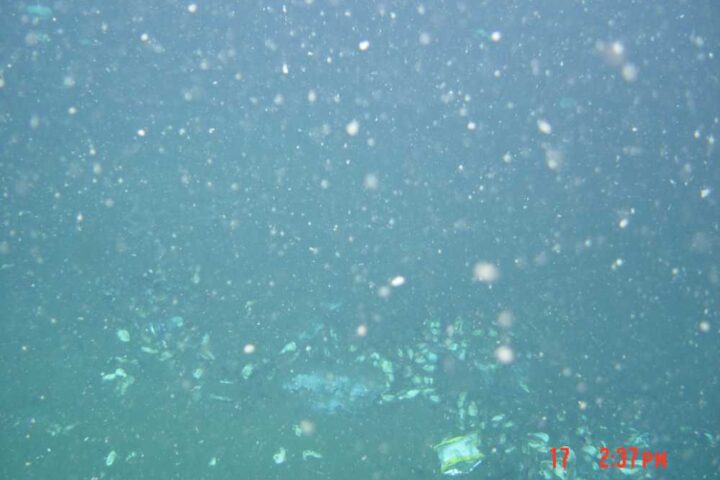

8% of all solid waste globally is accounted for by plastics, and this new enzyme is laser-focused on breaking it down, making it a crucial discovery. The magazine Nature published the findings as a patent filed by the scientists as they explored the enzyme’s practical applications.

The researchers want to scale up the manufacturing of FAST-PEtase so that it can be used in the environmental and industrial sectors. Landfill cleanups will be prioritized by the enzyme application. Environmental remediation and high-waste-producing businesses are included among other key applications.

About 90% of plastic isn’t recycled and either ends up in landfills, where long-lasting chemicals can be leached into the ground, or is burned or broken down at huge energy costs and with tons of pollution produced.

Enzyme requires much less energy for its production, and it works quickly. Plastic can be broken down in a day by bacteria armed with FAST-PEtase, turning it into base units that can be reused; otherwise, it would last 500 years in a landfill.

Similar Post

“Circular economy” is an economic approach that relies on developing new goods without waste or pollution. Plastic waste can be diverted into more useful products by recycling plastic more efficiently, and the entire industry can become more sustainable.

At present, humans use a “take/make/waste system,” in which raw materials are taken, a product is made, and then it is thrown away when it becomes damaged or no longer usable. A “circular plastic economy” is allowed by the enzyme, where waste is minimized and products are reused and recycled efficiently.

The scientists are ramping up production for real-world uses. Landfills, high-waste industries, and polluted natural areas in the future will be cleaned up by this product, according to the vision of the company.

The enzyme is an example of the potential of interdisciplinary research to solve complex problems. This discovery provides hope for a more sustainable future where materials can be recovered and reused in a circular and efficient manner.