Foundation Alloy, a company launched by MIT researchers, has developed a groundbreaking approach to creating advanced metals that could transform manufacturing across multiple industries. Their new solid-state metallurgy platform produces metal alloys twice as strong as traditional metals while cutting development time from years to months.

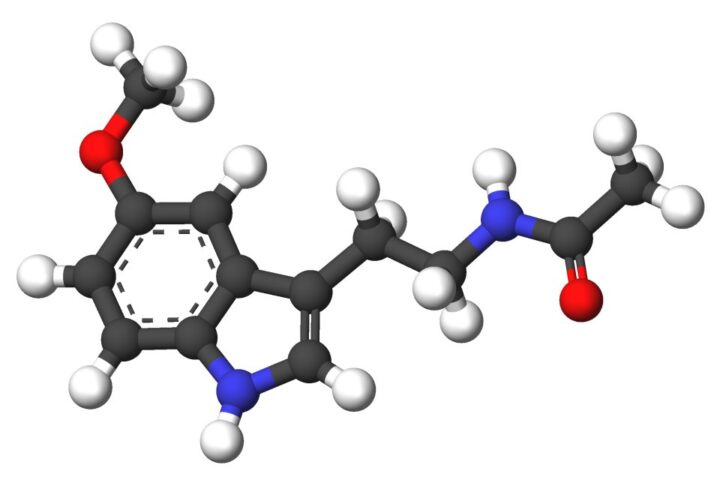

Unlike conventional metal production, which requires melting raw materials at extremely high temperatures, Foundation Alloy’s process never melts the metal. This unusual approach gives the company unprecedented control over the material’s properties at the microscopic level.

“This is an entirely new approach to making metals,” explains CEO Jake Guglin, an MIT graduate who co-founded the company with former MIT professor Chris Schuh, Jasper Lienhard, and Tim Rupert. “It gives us a broad set of rules on the materials engineering side that allows us to design a lot of different compositions with previously unattainable properties.”

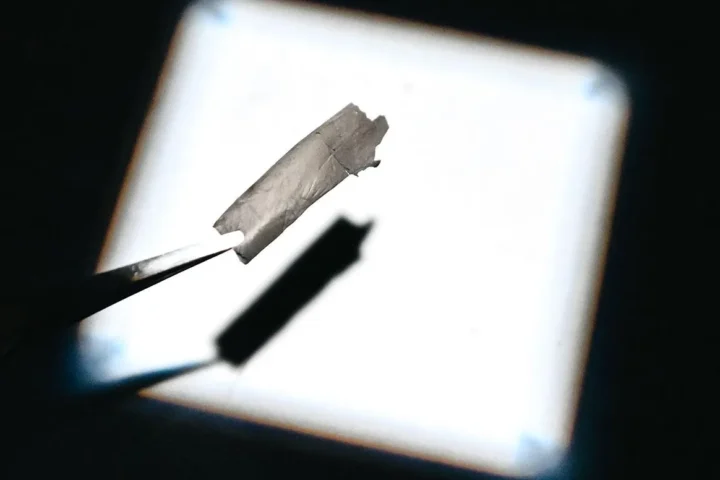

The company’s process starts with precisely mixed metal powders that are blended in what Guglin describes as “an industrial KitchenAid blender,” creating a mixture that’s uniform down to the atomic level. This powder can then be shaped using traditional methods like metal injection molding or 3D printing before being heated in a furnace – a process called sintering.

Importantly, this sintering requires far less heat than traditional methods, saving energy while giving better control over the metal’s microstructure. The process creates metals with grains 100 times smaller than conventional methods, unlocking superior properties.

“That’s where we get a lot of our performance boost from,” Guglin notes. “And by not needing those secondary processing steps, we’re saving days if not weeks in addition to the costs and energy savings.”

For industries like aerospace, defense, and energy, these improvements could be game-changing. In rocket and jet engines, for example, materials that maintain their strength at higher temperatures enable more efficient fuel use and more powerful systems. Foundation Alloy has already demonstrated this potential by creating a molybdenum-based alloy with three times the hardness of current market-leading materials.

The company is already shipping demonstration parts to manufacturers of planes, bikes, and cars, while also developing test components for defense and aerospace partners. They’ve received grants to develop critical components for nuclear fusion reactors and are exploring applications in AI hardware and data centers.

Similar Posts

The technology emerged from decades of research by Schuh, who joined MIT’s faculty in 2002 to study metal processing and properties. Rupert and Lienhard both earned their PhDs in Schuh’s lab, while Guglin connected with the team after hearing about their work during his MBA studies at MIT.

After founding the company in 2022 and licensing technology from MIT and UC Irvine, the team faced the challenge of scaling their laboratory process to industrial levels.

“There’s a lot of process engineering to go from doing something once at 5 grams to doing it 100 times a week at 100 kilograms per batch,” Guglin explains.

Foundation Alloy’s approach also solves another major hurdle in materials innovation: the traditionally lengthy and expensive process of developing new metal alloys. Because their development and production processes are nearly identical, they can scale new materials far more quickly than conventional manufacturers.

“We’re not beholden to the idea that this type of steel must solve this type of problem,” Guglin says. “We try to understand why that steel is failing and then use our technology to solve the problem in a way that produces not a 10 percent improvement, but a two- or five-times improvement in terms of performance.”

The company has secured $24.4 million in funding across three rounds, including a $7.5 million Series A round in May 2025. Investors include Material Impact, Engine Ventures, Alumni Ventures, America’s Frontier Fund, El Cap, and Yamaha Motor Ventures. Their innovative approach has earned them recognition as a 2025 Technology Pioneer by the World Economic Forum.

By eliminating energy-intensive melting and complex secondary processing steps, Foundation Alloy’s technology not only creates stronger metals faster but also does so more sustainably – potentially revitalizing American manufacturing leadership in metallurgy and providing critical materials for next-generation technologies.