Industries today need automation that keeps up with rapid product changes, tight delivery deadlines, and rising quality expectations. Traditional automation that relies heavily on fixed hardware can make updates slow, expensive, and difficult to scale in many plants. When markets shift or products require different specifications, physical reconfiguration can become a roadblock. Teams need better ways to improve operations, manage data, and keep uptime strong across every shift.

Teams need better ways to improve operations, manage data, and keep uptime strong across every shift. High-performance, software-defined automation for flexible industrial control helps companies respond faster to evolving market needs while maintaining stable, cost-efficient operations. High-performance, software-defined automation separates control logic from specific hardware. This helps companies respond faster and can improve stability; cost impact varies by implementation. Through virtualized control systems, remote configuration tools, and secure data flow, software-defined automation delivers a scalable foundation that adapts to modern demands.

What is Software-defined Automation?

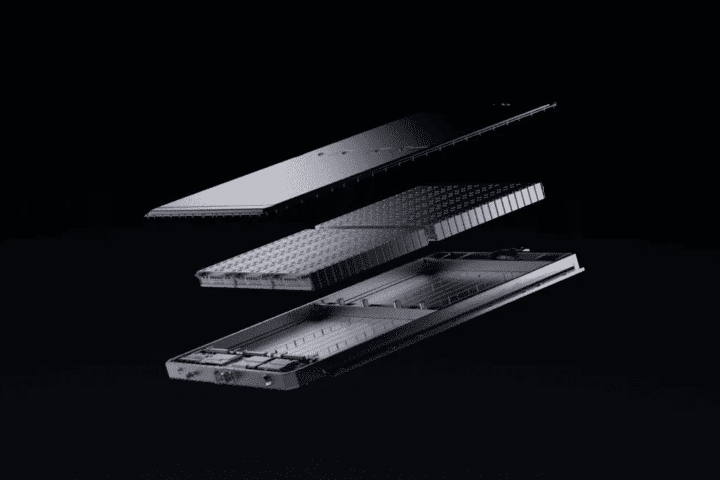

Software-defined automation refers to an approach where software controls operations rather than being tied to specific hardware. This decouples control logic from physical devices, allowing industrial processes to be managed, updated, and scaled primarily through software changes. It enables remote configuration, multi-site management from centralized platforms, and secure data flow between systems. This approach allows companies to adopt new technologies more easily, maintain system stability, and scale operations without complicated physical modifications.

Software-defined automation can improve the predictability of process changes and help reduce downtime during upgrades when paired with virtualized environments and staged deployments. Teams gain the flexibility to innovate continuously while keeping operations aligned with business goals.

8 Benefits of Software-defined Automation

These benefits show why new-age software industries are investing in software-defined automation to secure long-term performance and resilience.

1. Faster Response to Change

Software changes often replace or minimize physical modifications. Production switches for software-only changeovers can be reduced to minutes for recipe or logic changes; mechanical changes still take longer. Virtual PLCs and containerized control enable rapid re-deployment in many scenarios. This can prevent long stoppages and speeds up time-to-market when properly implemented.

2. Improved Operational Flexibility

Systems handle a wide range of product variations when designed with recipe-driven or parameterized approaches. Recipes, parameters, and control settings can be changed remotely through virtualized control systems. This supports personalized manufacturing and smooth transitions between product runs in facilities equipped with this capability.

3. Simplified Maintenance

Remote diagnostics can detect issues earlier through continuous monitoring of equipment health using sensors and predictive analytics. Automated logs speed root-cause analysis by providing detailed records of system behavior. With fewer onsite tasks in many deployments, plants can reduce labor hours and help lower the risk of costly unplanned downtime.

4. Lower Infrastructure Costs

In some architectures, virtualization and soft controllers may extend the useful life of existing automation hardware, though this depends on real-time constraints and licensing requirements. Companies can modernize through software rather than replacing entire control systems in many cases. This modernization approach can shift spending toward software and may reduce capital expenditures; return on investment varies by case and implementation specifics.

5. Stronger Data Visibility and Insights

Software-defined automation collects higher-frequency data from assets in real time; accuracy depends on instrumentation quality and calibration. Teams can track performance, measure energy use, and quickly identify inefficiencies through integrated monitoring systems. Better visibility helps guide continuous improvement initiatives and data-driven decision-making.

6. Better Cybersecurity Controls

Centralized management can orchestrate security updates and access policies in a controlled, safety-validated manner across facilities. While updates in operational technology must be staged and safety-aware rather than instant, unified oversight helps reduce cybersecurity risks and protects critical operations from evolving threats when aligned with standards such as NIST 800-82 and ISA/IEC 62443.

7. Scalable for Growth

New lines, products, or facilities can be deployed with consistent standards using validated software templates and centralized management. Expansion can be faster using these validated templates, subject to site-specific constraints such as network infrastructure, safety requirements, and local regulations. This approach supports more predictable scaling compared to traditional hardware-centric deployments.

8. Enhanced Workforce Productivity

Automation manages routine tasks while operators focus on quality checks, problem-solving, and system improvements. HMI dashboards provide clear, real-time guidance at workstations, making information more accessible to operators. This can make roles more skill-based and help boost confidence and productivity when combined with proper training and workforce development programs.

Conclusion

Software industries succeed when operations are flexible, safe, and ready to adapt without delay. Software-defined automation can enable this by improving visibility, simplifying upgrades, and strengthening performance across operations when properly implemented. It supports better decision-making and can improve security when aligned with established standards such as NIST 800-82 and ISA-IEC 62443.

Partnering with experienced operational technology and automation vendors can improve integration and support, though outcomes vary; organizations should evaluate solutions against open software-defined automation capabilities and cybersecurity maturity frameworks. Over time, organizations in digital lighthouse programs report productivity improvements, reduced lead times, and enhanced quality; results vary by implementation approach and organizational readiness.

Take the next step toward future-ready automation. Request a consultation to explore how software-defined solutions can strengthen your operations and prepare your teams for sustainable growth.