Oxford University is leading a £3 million project to create new battery materials that could make electric cars go farther, charge faster, and cost less. The three-year project, called 3D-CAT, aims to develop battery parts without using expensive metals like cobalt and nickel.

The cathode is a key part of lithium-ion batteries that largely determines how much energy they can store. Today’s best cathodes use cobalt and nickel, which are expensive and often come from limited sources. Cheaper options like lithium iron phosphate exist but store less energy, meaning electric cars can’t go as far on a charge.

“3D-CAT is an exciting opportunity to develop innovative new Li-ion cathode materials to support the British battery industry,” said Professor Robert House, who leads the project.

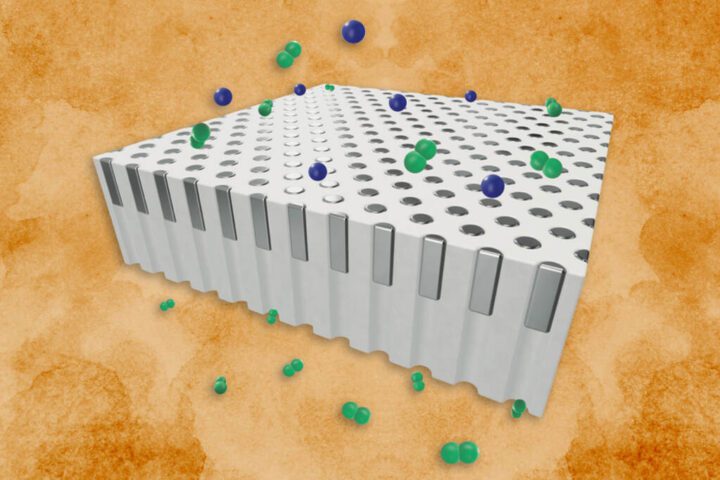

The researchers are focusing on materials called lithium-rich disordered rocksalts. These materials can store lots of energy but currently charge and discharge too slowly to be practical. They’re also made using a process called ball-milling, which uses too much energy and can’t easily be scaled up for mass production.

Similar Posts

Recent breakthroughs have shown that creating some order in these otherwise disordered materials can dramatically improve how lithium ions move through them. This discovery opens the way for a new class of three-dimensional cathode (3DC) materials that could combine high performance with practical manufacturing.

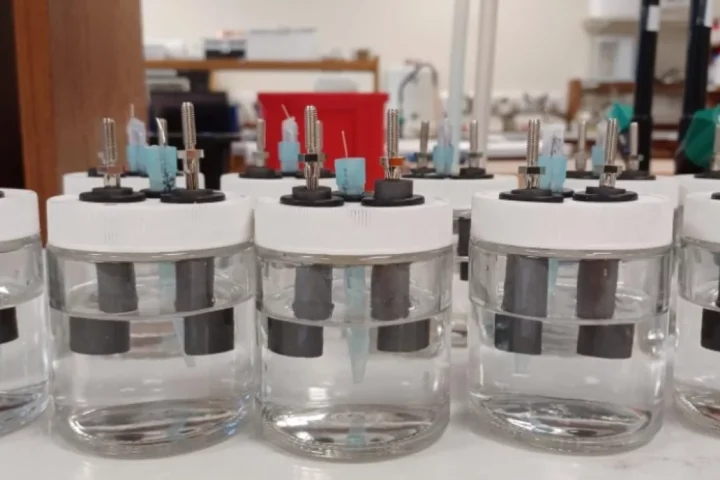

Over the next three years, the Oxford team will use their world-class research facilities to develop and test new cathode materials. They’ll work to understand exactly how the arrangement of atoms affects performance and develop cleaner, more energy-efficient ways to make these materials.

Industry partners, including the Centre for Process Innovation, will help ensure the research can be applied in the real world. Experts at CPI’s AMBIC battery scale-up facility will help develop manufacturing methods suitable for large-scale production.

“This project brings together brilliant minds, cutting-edge science and strong partnerships with industry to tackle one of today’s most pressing challenges—how to store energy cheaply and efficiently,” said Professor Jim Naismith from Oxford.

The 3D-CAT project is part of a £9 million investment by the Faraday Institution, the UK’s independent institute for battery research. The project is expected to run until September 2028, with funding beyond March 2027 to be confirmed in early 2026.

Success could significantly help reach climate goals by enabling electric vehicles with greater range and power while reducing battery costs. By eliminating the need for cobalt and nickel while matching their performance, these new materials could help make electric cars more affordable and sustainable.

This work builds on Oxford’s strong position in battery research, as the university already leads six major Faraday Institution projects in this field, including earlier work that laid the groundwork for 3D-CAT’s approach.