Corn-Based Nanofiber Membrane Removes Triclosan & Other Micropollutants

Electrospun cyclodextrin fibers were reported to remove ~90% triclosan in lab tests, with ~75% in the first 15 minutes at 11 mg/L and ~88% at ~6 hours.

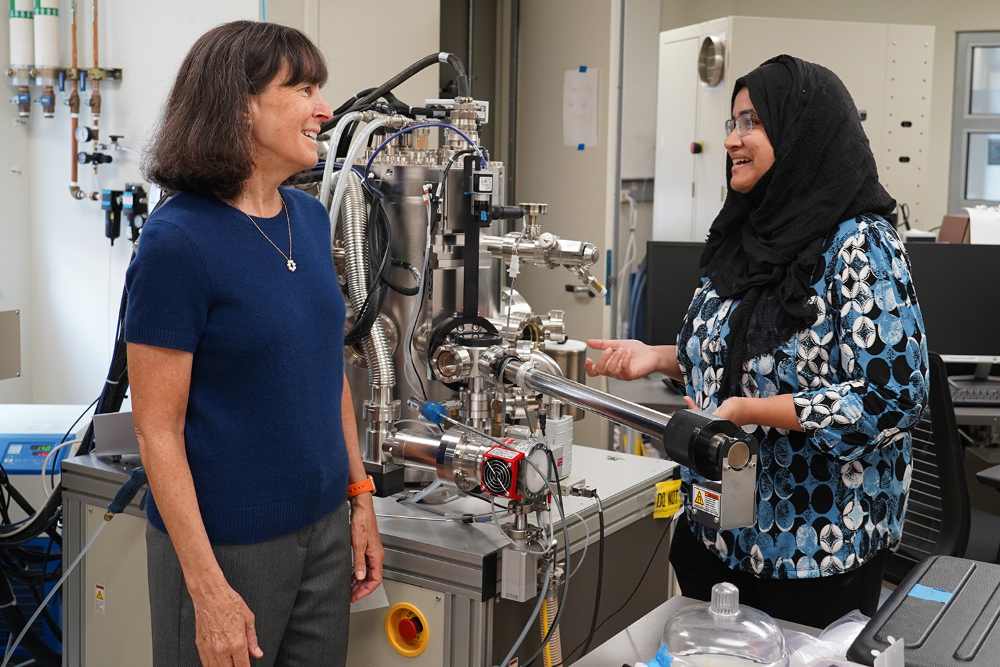

Cyclodextrin-based electrospun nanofiber membrane (feature image). Source: Cornell University.

Cyclodextrin-based electrospun nanofiber membrane (feature image). Source: Cornell University.Quick Intro

A Cornell research group reported a cyclodextrin-based fibrous membrane that removed approximately 90% of aqueous triclosan in lab testing and captured other micropollutants. The material is washable and reusable and is fabricated via electrospinning, producing fibers under 1 µm diameter for high surface-area adsorption. Full details are available via Cornell University.

Interactive: Triclosan Uptake vs. Time (Documented Points)

Use the buttons or slider to switch between reported times. Values are limited to the study’s noted measurements.

Materials & Method

- Electrospinning produced fibers <1 µm in diameter for high surface-area adsorption.

- Cyclodextrin formed the fiber itself; no extra support substrate required.

- Validation included rotating-frame Overhauser enhancement spectroscopy at Cornell NMR Facilities.

“The electrospinning produces a very thin fiber, less than 1 micron in diameter, which gives high surface area and excellent adsorption,” said Mahmoud Aboelkheir.

Reusability & Sustainability

- Membrane regenerated by washing (lower energy demand than restoring powdered adsorbents).

- Corn-starch–derived cyclodextrin is biodegradable.

Real-World Waters & Research Group

- Waters used in tests: Flat Rock, groundwater wells, and wastewater treatment plants.

- Lead author: Mahmoud Aboelkheir (Human Centered Design). Senior author: Tamer Uyar (Fiber Science). Co-authors: Asli Celebioglu, Damian Helbling, Ivan Keresztes.

Source & Further Reading

Full announcement: Cornell University. Explore related coverage on Karmactive: