CATL Fifth-Generation LFP Batteries Enter Mass Production with Sodium-Ion Platform

CATL (Contemporary Amperex Technology), the world’s largest battery manufacturer, has commenced mass production of its fifth-generation lithium iron phosphate (LFP) batteries, achieving breakthroughs in energy density and cycle life. Chairman and CEO Robin Zeng announced the development at the 2025 World Power Battery Conference in Yibin, Sichuan on November 12, 2025.

The company’s fourth-generation LFP batteries already outperform mainstream second and third-generation products in energy density, lifespan, and power output. CATL maintains leadership in ternary chemistry batteries deployed in its Qilin and Freevoy battery brands, expanding its technology portfolio across multiple chemistries.

Earlier in 2025, CATL launched the Naxtra sodium-ion battery platform, designed to reduce reliance on lithium resources while offering enhanced safety and lower carbon emissions. The sodium-based platform addresses low-temperature performance limitations of traditional lithium batteries, providing pathways for electric vehicle adoption in northern high-latitude regions.

Multi-Chemistry Platform Strategy

CATL’s approach spans three distinct battery chemistries, each optimized for specific applications and performance requirements

LFP Batteries

Sodium-Ion Batteries

Ternary Batteries

CATL Battery Technology Platforms

Visual overview of CATL’s advanced battery solutions and manufacturing capabilities

CATL’s research into all-solid-state batteries ranks among the most advanced globally, though large-scale commercialization is targeted for approximately 2030. The company stated that battery swap systems under development are compatible with future solid-state battery technology.

According to data from South Korea’s SNE Research, CATL held 36.6 percent of the global power battery market from January through September 2025. In China, CATL led the EV battery market in October with 36.14 gigawatt-hours of installed capacity, capturing 43 percent of the overall market. In the ternary lithium battery segment, CATL held a 72.79 percent market share, while the company captured 35.71 percent of China’s LFP battery market.

Global Battery Market Position

CATL’s commanding presence across worldwide battery installations reflects sustained investment in manufacturing scale and R&D capabilities

CATL contributed 120 GWh to China’s nearly 200 GWh of lithium battery exports in the first three quarters of 2025. The company operates 13 production bases worldwide, employing nearly 150,000 people. Over the past decade, CATL invested more than RMB 80 billion yuan (approximately $11 billion) in R&D, with RMB 15 billion yuan (approximately $2.1 billion) invested in the first three quarters of 2025 alone.

More than 20 million new energy vehicles globally are equipped with CATL batteries, reducing carbon dioxide emissions by about 14 million tons annually according to company statements. The company paid RMB 24.5 billion yuan ($3.44 billion) in taxes during the first three quarters of 2025.

Applications Across Transportation Sectors

CATL batteries extend beyond passenger vehicles into commercial transport, maritime operations, and aviation

Commercial Vehicles

CATL stated the Tectrans series has become the preferred choice for pure-electric heavy-duty trucks

Electric Vessels

According to CATL, nearly 900 electric vessels of various types are equipped with company batteries

Low-Altitude Aviation

CATL reported its two-ton eVTOL completed flight validations and secured Type, Production, and Airworthiness Certificates

Grid Storage

Energy storage systems support renewable integration and grid stability at utility scale

Beyond passenger vehicles, CATL batteries are deployed in commercial vehicles, electric vessels, and electric aircraft. The company stated its Tectrans series batteries have become the preferred choice for pure-electric heavy-duty trucks. Nearly 900 electric vessels of various types are equipped with CATL batteries, according to Chairman Robin Zeng’s statement at the conference.

In the low-altitude mobility sector, CATL’s two-ton eVTOL (electric vertical takeoff and landing) aircraft has completed multiple flight validations in complex environments. The aircraft secured Type Certificate (TC), Production Certificate (PC), and Airworthiness Certificate (AC), and is currently pursuing an Operation Certificate (OC), according to Zeng.

Battery Chemistry Characteristics

Comparative analysis of CATL’s three primary battery technology platforms

| Characteristic | 5th-Gen LFP | Sodium-Ion | Ternary (NMC) |

|---|---|---|---|

| Energy Density | Enhanced vs 4th-gen | Lower than LFP | Highest |

| Cycle Life | Extended longevity | 10,000+ cycles | Competitive |

| Cost Structure | Cost-efficient | Lowest material cost | Premium |

| Temperature Range | Standard operation | Cold climate capable | Standard operation |

| Safety Profile | High thermal stability | Enhanced safety | Requires management |

| Resource Availability | Moderate (lithium) | Abundant (sodium) | Limited (cobalt/nickel) |

| Primary Applications | Mass-market EVs, ESS | Grid storage, cold regions | Performance EVs |

| Production Status | Mass production (Nov 2025) | Planned late 2025 | Established |

CATL’s fifth-generation LFP batteries build upon the fourth-generation platform, which already outperformed mainstream second and third-generation industry products. The new cells achieve breakthroughs in energy density and cycle life, though specific numerical specifications have not been publicly disclosed.

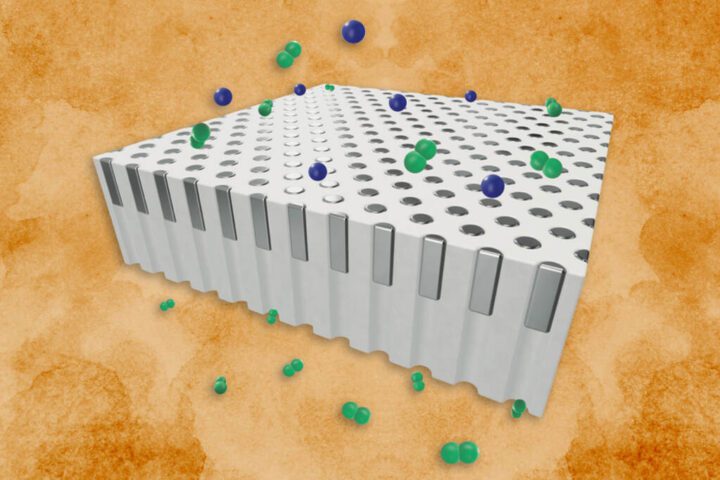

The sodium-ion chemistry addresses lithium supply concerns with abundant raw materials. Sodium is the sixth most abundant element in Earth’s crust, compared to lithium’s relative scarcity. CATL stated the Naxtra platform offers enhanced safety and addresses low-temperature performance limitations, making it suitable for high-latitude markets.

Global Manufacturing Network

CATL operates 13 battery production facilities worldwide with planned expansions in Europe and Asia

CATL maintains production facilities across China, with international operations in Germany and planned expansions in Hungary, Spain, and Indonesia. The company’s German facility commenced mass production in 2024, while the Hungarian plant’s core production line equipment has been delivered and is undergoing commissioning, expected to complete by end of 2025.

For the Spanish project, CATL completed preliminary approval procedures and formally established a joint venture with Stellantis, with plant construction scheduled to begin. The Indonesian battery industry chain project features planned capacity of 15 GWh for both power and energy storage applications, with production scheduled to commence in the first half of 2026.

The company’s battery recycling subsidiary Brunp achieved over 96 percent recovery rates for battery materials. In 2024, Brunp processed over 120,000 tons of waste batteries, equivalent to reusing batteries from up to 300,000 electric vehicles.

Battery Technology Development Path

CATL’s fifth-generation LFP batteries entered mass production in November 2025, building upon the performance gains established by fourth-generation cells. The company’s Naxtra sodium-ion platform launched earlier in 2025, with full-scale manufacturing scheduled for late 2025. CATL maintains its position as the world’s largest battery manufacturer with 36.6 percent global market share from January through September 2025.

The company operates across three primary battery chemistries: lithium iron phosphate, sodium-ion, and ternary lithium. CATL stated its all-solid-state battery research ranks among the most advanced globally, with large-scale commercialization targeted for approximately 2030. More than 20 million new energy vehicles worldwide currently operate on CATL batteries.

Applications extend from passenger vehicles to commercial trucks, electric vessels, and low-altitude aircraft. CATL invested over RMB 80 billion yuan in R&D over the past decade, with RMB 15 billion yuan invested in the first three quarters of 2025. The company reported its batteries reduce carbon dioxide emissions by about 14 million tons annually.