Diesel’s Environmental Crossroads

Diesel’s usefulness has never been in question. Transport fleets, industrial tractors, and agricultural workhorses depend on its torque-rich reliability. Yet the pressure to slash emissions grows heavier by the year, driven by regulation and public scrutiny. Performance tuning has shifted from raw horsepower bragging rights to surgical efficiency improvements that answer both operational needs and environmental demands. This is not about sacrificing power. It is about reshaping diesel’s future to stay relevant without leaving a trail of soot.

Performance’s Role in Sustainable Fuel Consumption

Better combustion is not just an engineer’s obsession—it directly trims fuel bills and carbon output. Optimized burn patterns translate into measurable savings. A well-tuned long-haul truck can eke out measurable fuel efficiency improvements—industry and peer-reviewed studies commonly cite single-digit percentage gains, typically ranging from 2–7% depending on vehicle age, duty cycle, and tuning approach—without dulling the pulling power needed for full payloads. In agriculture, precision-adjusted engines can deliver meaningful fuel savings during intensive harvest runs, though the magnitude varies depending on machine size, operating hours, and baseline efficiency. Lower consumption means fewer trips to the pump and less CO₂ streaming into the atmosphere, compounding gains across an entire fleet.

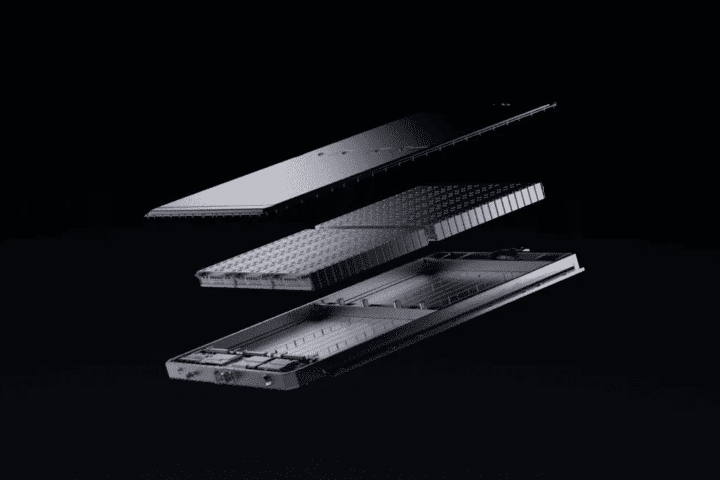

Precision Tuning: Technological Advances for Efficiency

Today’s tuning arsenal is rooted in data and targeted intervention. ECU remapping recalibrates fuel and air delivery curves to match specific workloads, with economy-focused tunes capable of yielding fuel efficiency improvements that vary broadly—from around 2% up to as much as 20% in some turbo-diesel applications—depending on the vehicle, baseline configuration, and duty cycle. Injection-timing optimization fine-tunes when fuel enters the cylinder, improving combustion stability and trimming particulate formation. Turbocharger trimming manipulates boost pressure to balance power output with fuel economy, a method supported by OEM test data showing reductions in consumption without noticeable loss in performance. Peer-reviewed studies confirm that these techniques stack together effectively, creating engines that run leaner, cleaner, and still push hard when called upon.

Emissions Aftertreatment Systems Enhancing Sustainability

Diesel particulate filters (DPFs) trap soot before it escapes. Selective catalytic reduction (SCR) transforms aggressive NOx pollutants into harmless nitrogen and water via urea injection. Exhaust gas recirculation (EGR) cuts peak combustion temperatures to suppress NOx at its source. These systems do not have to strangle performance. When paired with tuned engines, they maintain torque curves while meeting stringent emission thresholds. Well-integrated aftertreatment allows operators to stay compliant without surrendering operational capability, keeping machinery both muscular and environmentally acceptable.

Maintenance Matters: Sustaining Performance Over Time

When filters clog and sensors drift, tuning advantages evaporate. Regular air and oil filter changes, precise fuel-system cleaning, and sensor calibration keep efficiency gains alive. Ignore these basics and the engine will slide back into wasteful habits. Workshops should align inspections with manufacturer intervals, multi-point checks at every service, and immediate correction of detected faults. Time invested here keeps every earlier upgrade working as intended.

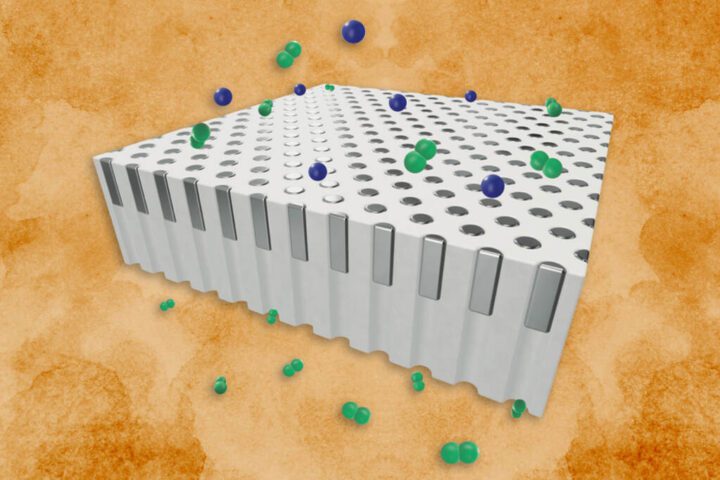

Cleaner Fuel Alternatives and Blending Strategies

Biodiesel blends like B20 are widely approved by major engine OEMs and can be used without modification in most modern diesel engines; B30 is gaining traction with select manufacturers—John Deere, for instance, approved B30 across its Tier 4 engine portfolio in 2025—but compatibility varies by engine make and model and operators should verify manufacturer approval before switching to higher blends. Synthetic diesel brings consistency in chemical composition, supporting optimized combustion. Ultra-low sulfur diesel cuts harmful emissions at the source and extends DPF life. Tuned engines and enhanced aftertreatment handle these fuels with ease, reducing greenhouse gas footprints across the supply chain. Blending strategies let operators walk the fine line between cost control, engine protection, and environmental stewardship.

Integrating Parleys diesel performance for Eco-Friendly Gains

Placing Parleys diesel performance into the sustainability equation is straightforward. Their calibrations and component packages add precision to combustion control, extend service life of mechanical systems, and lower exhaust pollutants. Integrated correctly, these upgrades complement fuel-saving and emission-reduction strategies rather than operate in isolation. It is about tightening every bolt of the efficiency puzzle.

Strategic Operations for Greener Diesel Fleets

Technology alone will not carry the day. Route optimization software slashes unnecessary miles. Driver efficiency training corrects wasteful habits like aggressive acceleration or idling. Telematics deliver real-time data, exposing underperforming vehicles and allowing prompt corrective measures. Each operational tactic reinforces the work done under the hood, ensuring that gains in performance and emissions reduction are not lost in careless execution.

Charting the Next Mile in Eco-Friendly Diesel Performance

The roadmap is clear. Precision tuning, robust aftertreatment, disciplined maintenance, cleaner fuel use, strategic integration of Parleys diesel performance solutions, and tactical fleet management combine into a sustainable diesel playbook. Monitor fuel metrics. Track emission outputs. Adjust as conditions shift. Continuous measurement is the only way to keep diesel engines delivering power without leaving an environmental debt.