Scientists at Binghamton University have developed a groundbreaking biobattery that uses bacteria and 3D-printed stainless steel to generate electricity without toxic chemicals. The innovation marks a significant leap in sustainable power generation for small electronics.

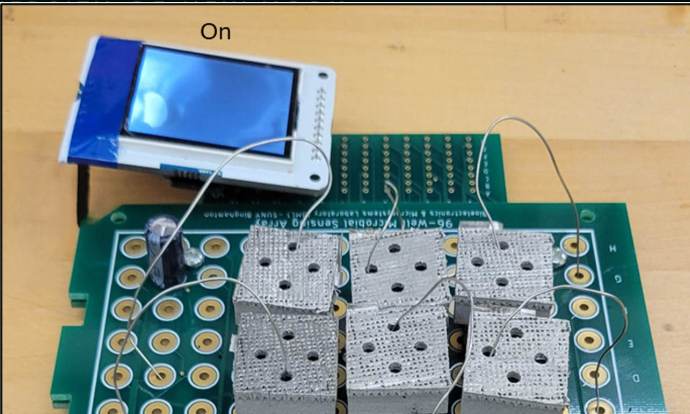

Professor Seokheun “Sean” Choi, who has been developing bacteria-powered batteries for over a decade, found the solution to a persistent material problem just one floor below his office. By teaming up with Assistant Professor Dehao Liu, an expert in laser powder bed fusion (LPBF) technology, they created a biobattery that produces nearly 1 milliwatt of power – enough to run a 3.2-inch LCD screen.

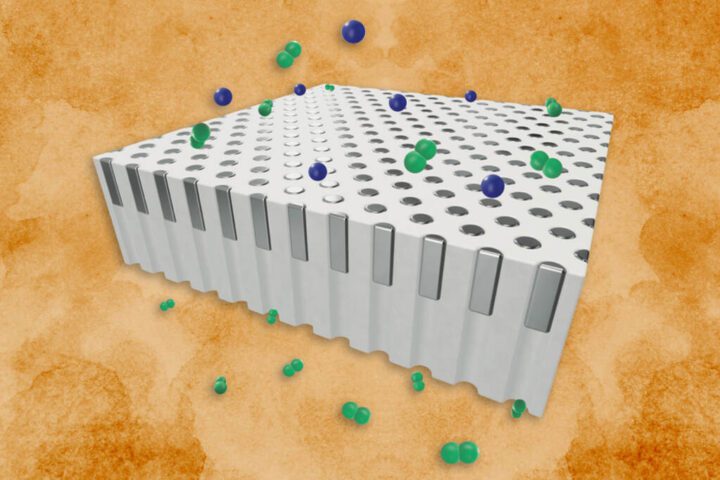

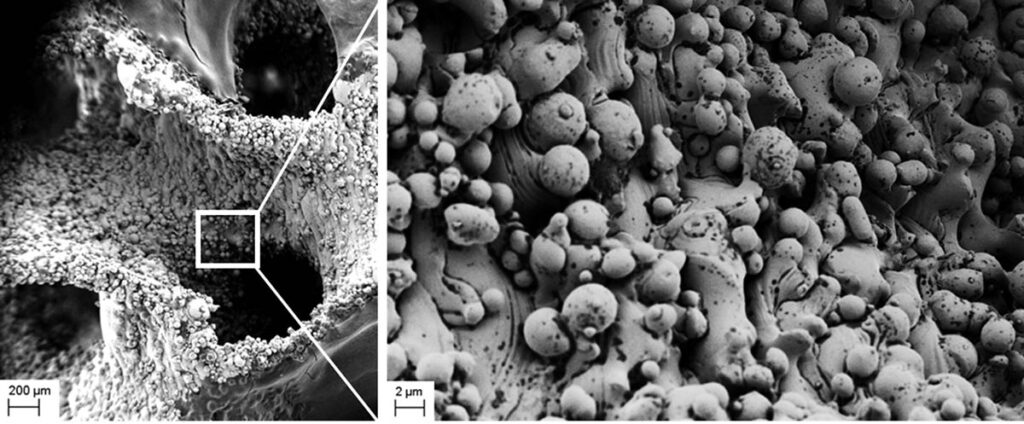

“A two-dimensional anode is not efficient,” Choi explains. “Nutrients will not be delivered effectively to the bacteria, and their waste cannot go out effectively.” This limitation had plagued earlier versions of his biobatteries, which used either flat surfaces or less durable materials.

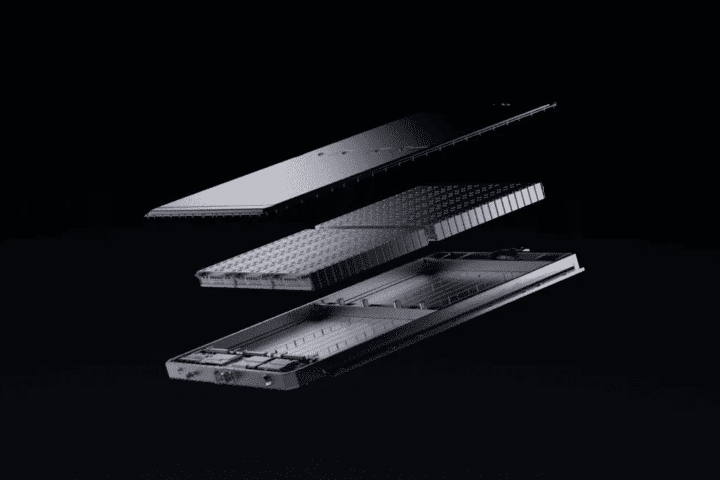

The breakthrough came through the specialized 3D printing technique that Liu specializes in. LPBF works by depositing thin layers of metal powder and selectively melting them with a laser, creating precise three-dimensional structures. This allowed the team to control critical features like porosity and surface roughness – impossible with commercial stainless steel mesh.

“LPBF is ideal for biobatteries because it enables high-precision, customizable 3D structures with complex geometries, essential for maximizing surface area and energy density,” Liu stated.

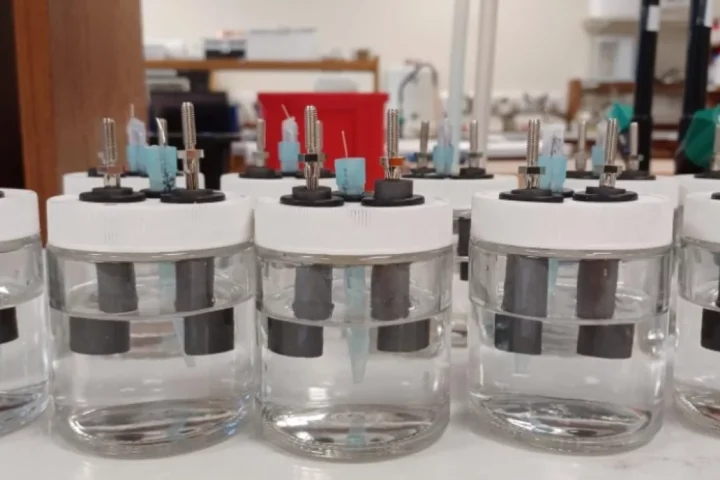

The bacteria-powered system consists of three main components: a cathode (positive electrode), an anode (negative electrode), and a membrane where ions move to generate electricity. The specially designed stainless steel anode serves as home for electrogenic endospores – dormant bacteria that activate under favorable conditions and produce electricity through an electrochemical reaction.

Similar Posts

Unlike traditional batteries that require lithium and other potentially harmful materials, these biobatteries use only bacteria and stainless steel, making them more sustainable. Another advantage is reusability – the bacterial cells can be detached and reused multiple times without power loss.

The research team, which includes Assistant Professor Anwar Elhadad, PhD student Yang “Lexi” Gao, and Liu’s PhD students Guangfa Li and Jiaqi Yang, published their findings in the journal Advanced Energy & Sustainability Research. Their work was supported by a 2024 grant from the National Science Foundation.

“I’m so happy about this collaboration,” Choi said. “It makes this iteration of the biobattery very meaningful to me.”

The Binghamton team assembled the components “like Lego bricks,” using 3D printing to create not only the anode but also the sealing cover and cathode. By stacking multiple batteries, they achieved nearly 1 milliwatt – one of the highest power outputs in Choi’s years of biobattery research.

Looking ahead, the scientists aim to streamline production by developing a unified printing method for all battery components. They also plan to implement a power management system similar to those used in solar cells to improve energy harvesting efficiency.

This technology could eventually power small, autonomous devices like Internet of Things sensors, which increasingly connect our everyday objects. Choi has previously worked on biobatteries for remote environments and even ingestible versions that could function inside the human digestive system.

The innovation represents a significant step toward creating sustainable, self-powered electronic systems that can operate in various environments without external power sources.