The Indian Institute of Technology Madras (IIT Madras), in collaboration with the Indo-German Science and Technology Centre (IGSTC), has developed and deployed an innovative wastewater treatment technology for the textile industry. The system, which combines Electrochemical Ozone Oxidation Process (ECOOP) with Capacitive Deionization (CDI), has been operating at Kunnankalpalayam Common Effluent Treatment Plant (CETP) in Tirupur since December 1, 2023.

According to IIT Madras, the pilot project was recently scaled up to process 400 liters per day in early 2025. Led by Prof. Indumathi M. Nambi of IIT Madras’s Environmental and Water Resources Engineering Division, the technology is reported by the institute to have achieved 96% color removal and 60% Chemical Oxygen Demand (COD) reduction in textile wastewater.

“This innovative approach reduces the number of RO units required in the treatment plant, ultimately lowering the total treatment cost by 25% and cuts down the RO infrastructure cost by 75%,” said Prof. Nambi in the IIT Madras press release. “It efficiently removes colour and organic pollutants without the use of Chlorine which is reported to produce harmful byproducts.”

The technology addresses a critical environmental challenge in India’s textile sector, which contributes approximately 5% to the nation’s GDP and 12% of export earnings, but is responsible for about 20% of global industrial water pollution, according to World Bank reports.

In Tamil Nadu, textile industries have been mandated to implement Zero Liquid Discharge (ZLD) systems since 2008—the first such requirement in India, followed by national guidelines from the Central Pollution Control Board in 2015.

Similar Posts

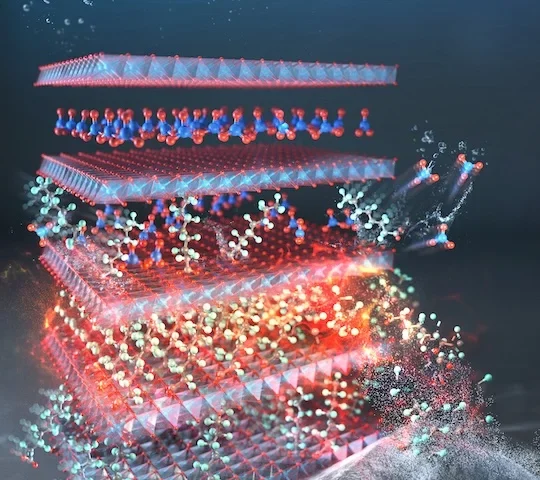

The ECOOP-CDI system works by recognizing that only 10% of effluent in a dyeing unit constitutes high Total Dissolved Solids (TDS) dye bath, while the remaining 90% is wash water with lower TDS. The ECOOP component effectively degrades dyes and organic pollutants without producing sludge, while CDI removes salts with lower energy consumption compared to conventional RO systems.

“This approach combines an advanced oxidation process with Capacitive Deionization for efficient organic and salt removal,” Prof. Nambi explained in the IIT Madras release. “The ECOOP process effectively degrades dyes and other organic pollutants in textile wastewater, achieving organic mineralisation without producing sludge.”

The pilot plant was inaugurated by Shri T. Christuraj, IAS, District Collector of Tirupur, as confirmed by The Hindu and Times of India reports. According to IIT Madras, the system has demonstrated consistent performance, maintaining 94-97% color removal and 58-62% COD reduction across various dye types including reactive, direct, and sulphur dyes.

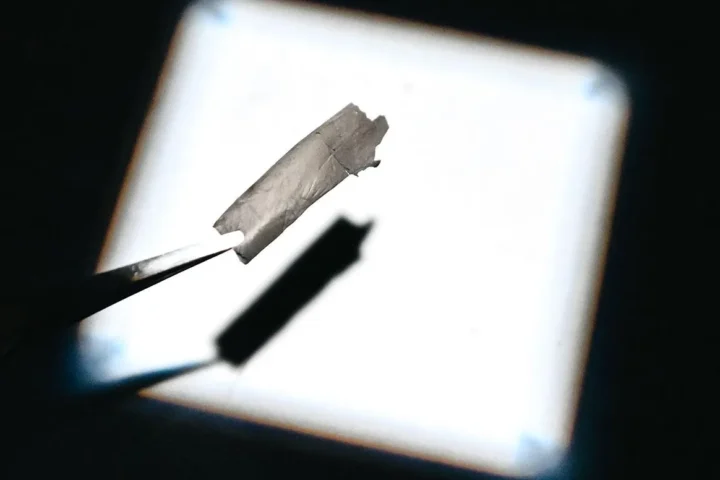

The technology development included extensive lab testing with synthetic wastewater in volumes ranging from 500 ml to 50 liters before scaling up to the current system. In November 2023, an ecotoxicology workshop organized by IIT Madras and SRM Institute used zebrafish assays to verify that ECOOP-treated effluent showed negligible acute toxicity compared to chlorinated controls, with lectures by experts including Prof. Henner Hollert from Goethe University and Dr. S.R. Marigoudar from NCCR, Chennai.

The project represents a significant advancement for Tirupur’s textile industry, where over 700 dyeing units now operate ZLD systems following court mandates to protect the Noyyal River, which had previously suffered severe pollution. The Indian ZLD market, valued at approximately INR 450 crore in FY 2020, is projected to reach INR 650-750 crore by FY 2024, according to Frost & Sullivan market reports.

Looking ahead, IIT Madras reports it is working to optimize the system for smaller dyeing units that don’t have RO systems. The institute indicates it has applied for a provisional patent on the ECOOP-CDI process, though this cannot be independently verified in public patent databases at this time.

The IIT Madras project was undertaken in collaboration with Goethe University, RWTH Aachen University, Eurofins, and Tamil Nadu Water Investment Company (TWIC), bringing together international expertise to address local environmental challenges. According to IIT Madras, the project aligns with multiple UN Sustainable Development Goals including clean water, responsible consumption, and climate action.