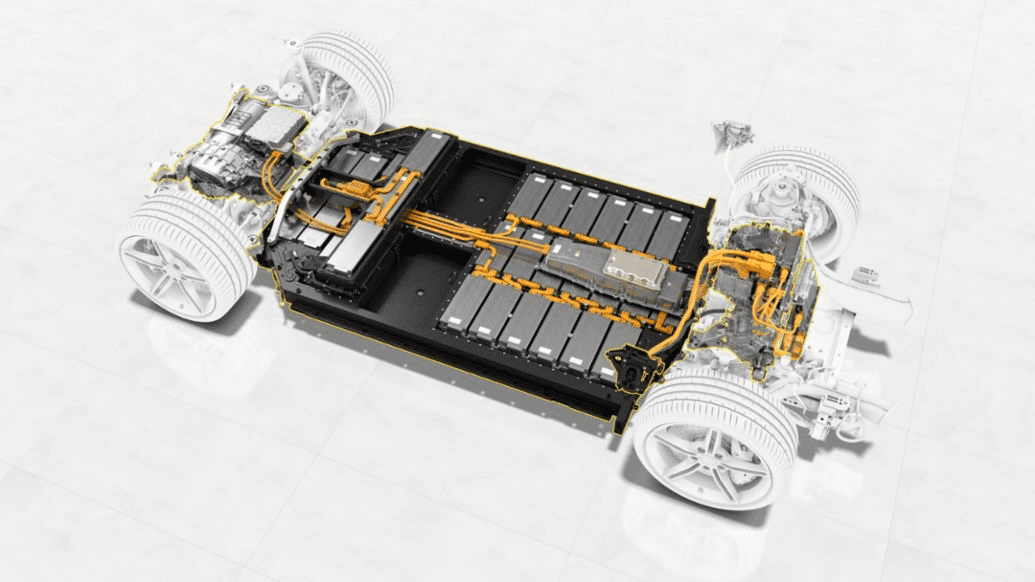

The electrification efforts of Porsche have generated a positive reception, particularly with the Taycan, which offers an exceptional driving experience among electrical vehicles. Although its range is decent but not class-leading, the J1 platform used by Porsche and also provided to Audi for the e-Torn GT showcases impressive capabilities in terms of charging through its 800-volt architecture.

Contributing to the perception of EVs as fun and dynamic vehicles, Porsche’s first foray into the electric vehicle market has been highly successful, with even greater advancements expected in the future. Stemming from the scarcity of charging stations compared to gas stations, range anxiety is a genuine concern that will see improvements as Porsche collaborates with Cellforce Group and Group 14 Technologies to enhance lithium-ion batteries.

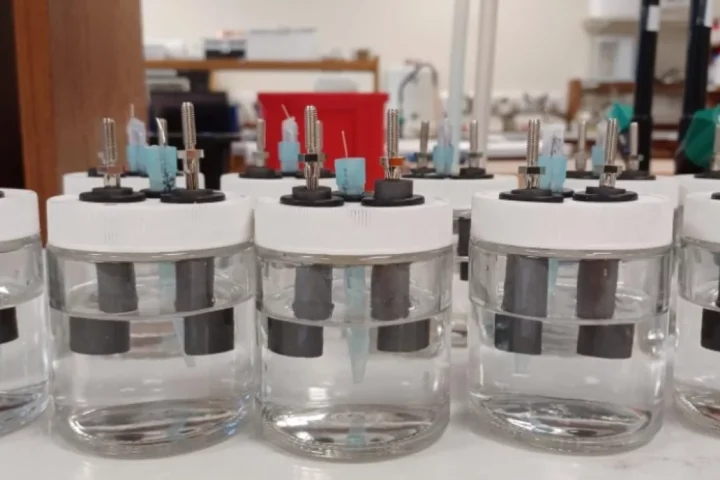

Being multi-component systems, lithium-ion batteries can achieve current range, charging, and safety requirements, but modifying certain ingredients can result in significant performance enhancements. Thanks to silicon’s high energy density and abundant availability in the Earth‘s crust, exploring silicon as an alternate anode material can increase the total capacity of lithium-ion batteries.

Boasting a range of over 300 miles, the all-new Porsche Madan E V, based on the PPE Platform co-developed with Audi, has been spotted testing at the Nürburgring and is expected to enter the US market by 2023. Aligning with the industry’s broader push toward reducing carbon footprints, the Madan EV represents Porsche’s commitment to transitioning from combustion engines to complete EVs and hybrids.

Specifically designed for high-riding vehicles, Porsche’s Madan EV utilizes the PPE platform, while the J1 platform is optimized for low-riding structures like the Taycan. There is a challenge in implementing silicon in batteries, such as increased particle size when silicon absorbs lithium, resulting in mechanical stress that reduces battery lifespan.

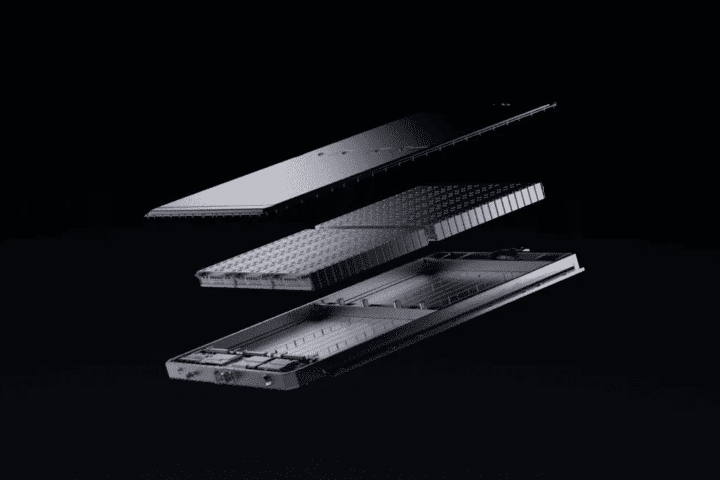

Aiming for up to 80% silicon content, Cellforce Group is collaborating with Porsche to achieve anodes with a high proportion of silicon, thereby addressing longevity concerns. Integrating cells directly into the battery pack, “cell-to-pack” technology, eliminates small-scale parts in current batteries, allowing for larger cell sizes, improved storage, better cooling, and denser packaging.

It is anticipated that medium-term innovations, including silicon anodes and dense battery cell packaging, will enhance Porsche’s future EVs, potentially leading to a range of up to 1,300km (807.78 miles) and a 30–50% range increase. Charging time can be significantly reduced utilizing silicon anodes, enabling a 10-80% charge in less than 15 minutes, compared to the Taycan’s 22.5 minutes using the 800-volt architecture.

Similar Post

Charging capacities can be increased with higher proportions of nickel in the cathode, but to fully leverage high-power batteries, charging stations will require active cooling to efficiently deliver 500 kw of power. The same electrical setup as the Taycan will be utilized by the Madan EV, but it is expected to offer a superior range, and customer preference in the US leans toward larger battery packs with better range.

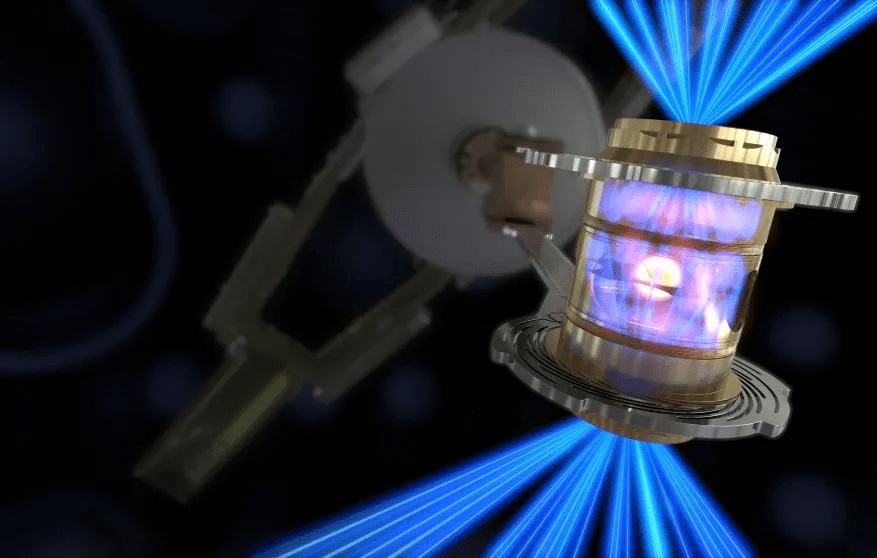

Details of the design of the Madan EV remain mostly undisclosed, but spy shots suggest distinct front-end styling, sleeker headlamps, and a coup like body-line. Solid-state batteries are viewed by Porsche, like other EV manufacturers, as a game-changing technology due to their potential for increased compactness, enhanced safety, and higher energy density.

A solid supporting electrolyte is employed by solid-state batteries instead of a liquid solution, which contributes to their reputation for safety and their potential as a future battery technology.The aim of Porsche’s pursuit of solid-state batteries is to replace the classic separator with a thin layer of solid electrolyte, serving as both electrolyte and separator in one. Still in progress, solid-state battery development is not yet ready for mass production, but Porsche’s focus on lithium-silicon batteries and the advancements.