Nanofiber Filter Turns Building Vents Into Carbon Capture Devices

University of Chicago develops filter that captures CO₂ with 92.1% efficiency while cutting HVAC energy costs by up to 21.66%

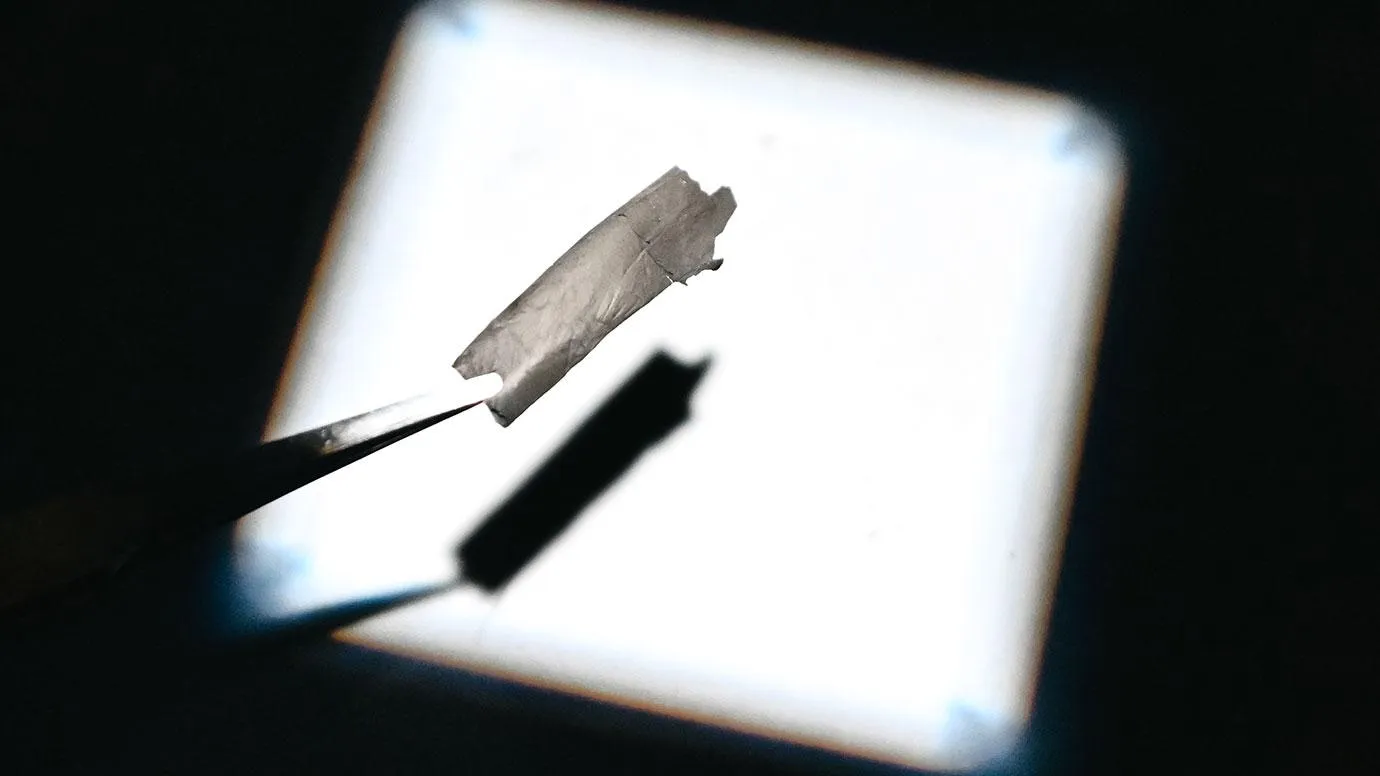

A carbon nanofiber–based direct air capture filter developed at the University of Chicago, designed to integrate into building HVAC systems and remove carbon dioxide directly from circulated indoor air. (Photo: University of Chicago Pritzker School of Molecular Engineering)

A nanofiber air filter developed at the University of Chicago could turn existing building ventilation into carbon-capture devices while cutting homeowners’ energy costs. Published in Science Advances, researchers from the lab of Assistant Professor Po-Chun Hsu in the Pritzker School of Molecular Engineering developed a distributed carbon nanofiber direct air capture filter that could turn every home, office, school or building into a carbon-capture system.

A life-cycle analysis shows the filter is 92.1% efficient in removing carbon dioxide from the air, even after factoring in CO₂ released from manufacture, transportation, maintenance and disposal. This addresses a problem faced by many direct air capture technologies that consume more energy than they save.

“Every building already has ventilation systems that move large volumes of air every day,” said first author Ronghui Wu, now an assistant professor at Nanyang Technological University. “By integrating our carbon-capture filters into these systems, we can remove carbon directly from the air without building new plants or using extra land.”

How It Works: Carbon Nanofiber Technology

Carbon Removal Efficiency

Net CO₂ removal from cradle to grave, including all manufacturing and disposal emissions

Energy Savings

Reduction in HVAC energy consumption by decreasing outdoor air intake needs

CO₂ Capacity

Carbon nanofiber with polyethylenimine achieves high adsorption capacity

Cost Per Tonne

Estimated cost for capturing and storing one tonne of CO₂ from direct air

The carbon nanofiber-based polyethylenimine (PEI) material creates a reusable filter that slots into existing HVAC systems, similar to high efficiency particulate arresting (HEPA) filters. Unlike HEPA filters that go to landfills every six months to a year, these carbon-capture filters can have the CO₂ removed regularly and be returned to service.

On the largest possible level, replacing every building air filter with this model could remove up to 596 megatonnes of carbon dioxide from the air—the equivalent of taking 130 million cars off the road for a year. This potential makes it competitive with other carbon capture innovations being developed.

The Carbon Capture Process

CO₂-rich air circulates through HVAC system

Nanofiber filter binds CO₂ molecules chemically

Sunlight releases captured CO₂ for reuse

“Normally, air-conditioning systems need to pull in a lot of outside air to keep indoor carbon dioxide levels low,” Wu explained. “Our filter removes carbon dioxide inside the building, so the system doesn’t have to bring in as much outside air. That means less air needs to be heated or cooled, which reduces energy consumption in HVAC.”

According to the research published in Science Advances, HVAC ventilation accounts for 30% of global energy consumption and emits 10% of greenhouse gases globally. By reducing the need for outdoor air intake, buildings can significantly lower their energy footprint while maintaining healthy indoor air quality.

Applications Across Asia, India and Africa

🇮🇳 India

High-rise apartments, IT parks, schools and hospitals with existing AC infrastructure offer immediate retrofit potential. India’s abundant sunlight makes solar regeneration cost-effective.

🌏 Southeast Asia

Dense urban towers, transit hubs and malls with centralized HVAC maximize impact. High cooling demand makes energy savings particularly significant.

🌍 Africa

Schools, clinics and offices benefit from hybrid natural-mechanical ventilation. Solar-only regeneration requires no grid dependency.

The filter was specifically designed with excellent solar absorptivity, enabling CO₂ removal through solar-thermal heating. “It has to be able to regenerate using renewable energy,” Hsu said. “The most common way to regenerate CO₂ with solvent is by heating it up. If you burn fossil fuels to heat up the solvent, then you will probably end up emitting more carbon dioxide than you capture.”

This approach contrasts with centralized direct air capture facilities that require massive land use and capital investment. Hsu likens it to solar power—a technology once confined to utility-owned solar farms, but now a network of large farms and small rooftop panels working toward the same energy goal.

“These rooftop panels are possible because sunlight is more or less uniform. The CO₂ from air is similar. We propose, using experiment and computation to demonstrate, that indeed we could retrofit our buildings to be part of the decarbonization effort.”

Assistant Professor Po-Chun Hsu and PhD student Yuanke Chen of the University of Chicago Pritzker School of Molecular Engineering, part of the research team behind the nanofiber air filter that enables carbon capture within existing building ventilation systems. (Photo: University of Chicago Pritzker School of Molecular Engineering)

Calculate Your Building’s Impact

Estimate potential CO₂ capture and energy savings based on building size

*Based on 92.1% capture efficiency, typical HVAC usage, and 21.66% energy reduction

Beyond climate benefits, the filter improves indoor air quality. “This kind of air filter can also improve indoor air quality, especially in places like classrooms and offices where many people share the same space,” Wu said. “By keeping indoor carbon dioxide levels low, it helps people stay more alert, focused and healthy.”

This is particularly relevant in cities facing severe air quality challenges. High indoor CO₂ levels impair cognitive function, decision-making and focus—problems common in crowded classrooms and offices.

Technical Specifications

| Specification | Value | Details |

|---|---|---|

| Material Composition | CNF + PEI | Carbon nanofiber with polyethylenimine coating |

| CO₂ Adsorption Capacity | 4 mmol/g | Effective in humid environments |

| Life-Cycle Efficiency | 92.1% | Cradle-to-grave carbon removal |

| Regeneration Method | Solar/Electric | Low carbon footprint regeneration |

| Energy Savings | Up to 21.66% | Reduction in HVAC energy consumption |

| Global Potential | 596 Mt CO₂/year | Equivalent to 130M cars off roads |

| Cost Estimate | $209-668/tonne | CO₂ capture and storage cost |

| Pressure Drop | 76 Pa | At 77 cm/s face velocity |

Hsu and Wu envision an ecosystem where municipal waste management systems collect filters weekly with garbage and recycling. “They would have these saturated filters from household ventilation systems and commercial buildings, then replace them with new ones,” Hsu said. “They’d ship the saturated one to a centralized facility to dissolve the CO₂ or make it into highly concentrated CO₂ to capture or, even better, convert to high-value chemicals or fuel.”

This circular economy model transforms carbon capture from an expense into a resource recovery system. The extracted CO₂ can be converted to fertilizer, dry ice or industrial chemicals, creating revenue streams that offset filter costs.

The research builds on growing efforts to address record CO₂ levels in the atmosphere. Combined with renewable energy expansion and other mitigation strategies, distributed building-based carbon capture could contribute significantly to climate targets.

The development of the carbon nanofiber direct air capture filter by the University of Chicago Pritzker School of Molecular Engineering was detailed in Science Advances. A carbon removal efficiency of 92.1% was reported for the device from cradle to grave. The potential for these filters to be integrated into existing HVAC infrastructure was noted, with estimates suggesting global removal of 596 megatonnes of CO₂ annually upon widespread adoption. Energy savings of up to 21.66% for building operations were projected due to reduced ventilation requirements. A proposed waste management cycle involving centralized collection and solar regeneration of filters was outlined by the researchers.

Primary Sources & References

Research Publication

Institutional Sources

Related KarmActive Coverage

- Airbus Direct Air Capture Technology Tackles Climate Change

- MIT’s Breakthrough in Efficient Carbon Capture

- America’s First Commercial Carbon Capture Facility by Heirloom

- The Impact of Air Pollution: From Cradle to Grave

- Mumbai’s Air Quality Crisis

- WMO: Global CO₂ Levels Hit Record High

- India’s Quest to 500 GW Renewable Energy by 2030